Speak to one of our experts.

Speak to one of our experts.

2 December 2025

If you’ve ever been halfway through a project and realised the exact bush, spacer or mount you need doesn’t exist, you’ll know the sinking feeling that comes with it. That’s exactly why we manufacture our Polyurethane Bar—a machinable polyurethane rod that lets you create the precise component your build demands.

In this post, we’ll run through what makes polyurethane bar so handy, why it’s better than trying to adapt an ill-fitting part, and how it can save the day for classic restorers, fabricators, off-roaders and anyone who enjoys making their own solutions.

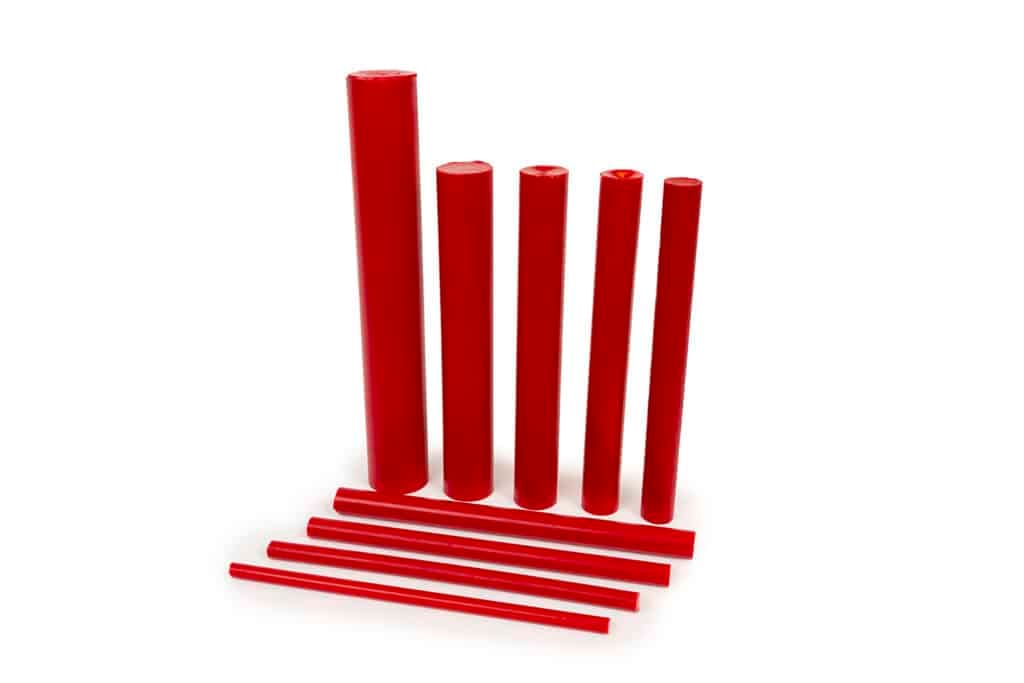

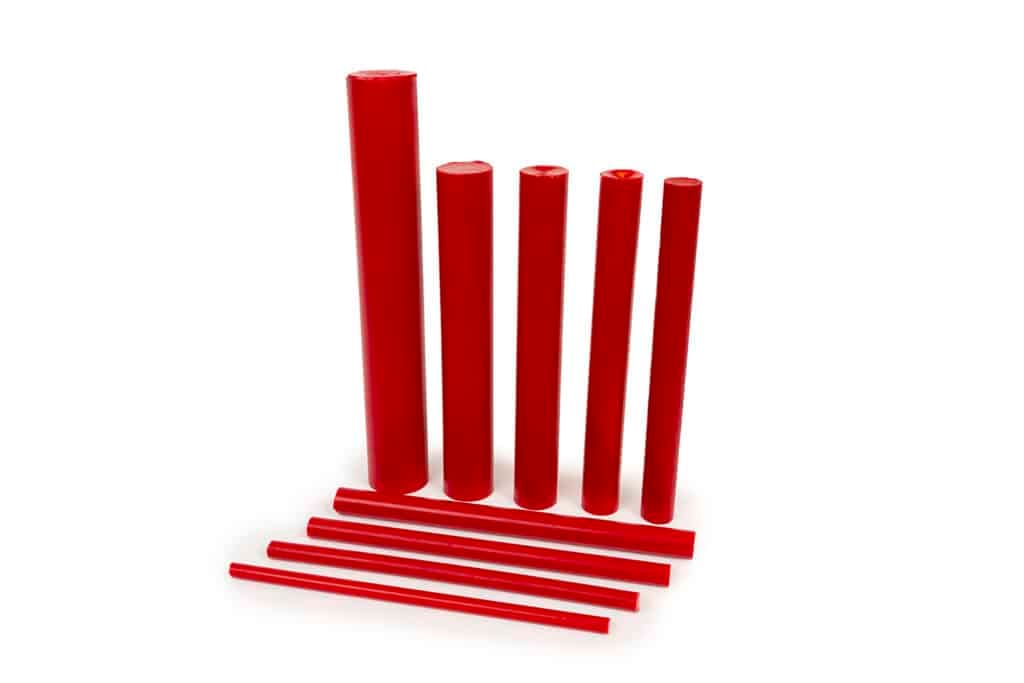

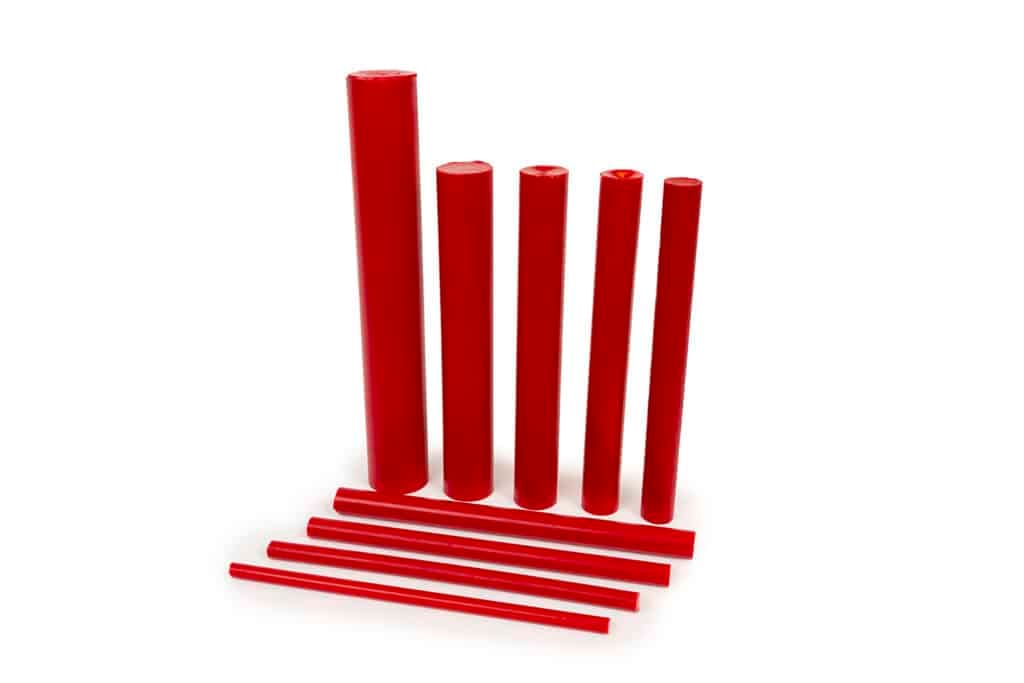

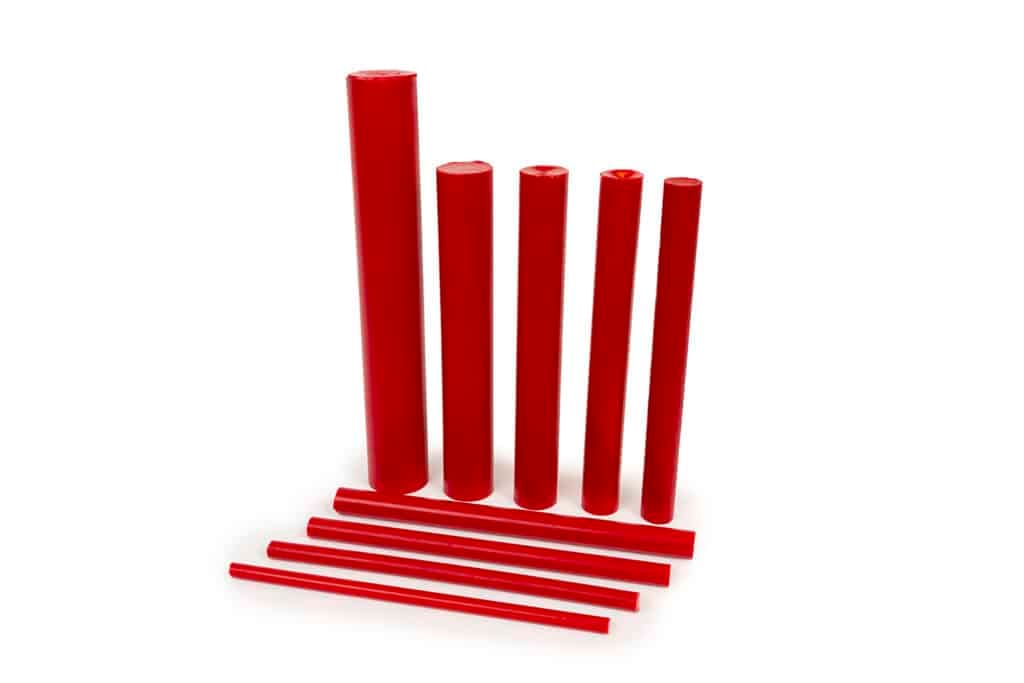

A polyurethane bar (sometimes called a polyurethane rod) is exactly what it sounds like: A solid length of high-quality polyurethane that you can machine on a lathe. We produce it in a variety of diameters, so you can pick the size closest to your end goal and turn it down to your exact measurements.

It’s made from the same material we use in our production suspension bushes—so you’re getting the durability, flexibility and impressive tear strength you’d expect from proper automotive-grade polyurethane.

We’ve seen plenty of people try to modify a rubber bush or shave down something “close enough” to get themselves out of trouble. Honestly, it’s rarely worth it. Rubber deforms, collapses, and generally doesn’t appreciate being re-imagined into something it was never meant to be.

Machining a lathe-ready polyurethane rod, on the other hand, gives you:

You’re not fudging anything. You machine the part to exactly the dimensions you want—outer diameter, inner diameter, length, chamfers, the lot.

Polyurethane laughs in the face of oils, road grime, UV, compression cycles and general abuse. If you’re going to the trouble of machining a custom part, you may as well make it last.

Need to make a second bush? A spare? A mirrored pair? Easy. Same bar, same material, same process.

Honestly, anyone with a lathe. But the biggest winners tend to be:

Some old cars use oddball bush sizes the aftermarket never produced in polyurethane. With a polyurethane bar, you can recreate them exactly—no compromise, no hunting scrapyards, no praying for NOS.

If you’re designing your own suspension arms, engine mounts, subframe bushings, vibration isolators or even just mounting an intercooler / uprated radiator, a raw polyurethane rod lets you tweak your design until it’s bang on.

Land Rover owners, I’m looking at you. When you’re experimenting with geometry, lift kits or custom arms, polyurethane rods let you build the right isolator or bush for your setup.

Sometimes a standard bush is too soft, too tall, too wide, or not quite the right hardness. Machined polyurethane lets you dial in the response you want.

If you’ve handled nylon bar or other engineering plastics, this isn’t much different. It cuts cleanly, holds tolerances nicely, and doesn’t fight you like some softer elastomers.

A few quick tips:

Use sharp tools

Take moderate cuts (don’t try to peel massive chunks off)

Keep the part well supported to avoid deflection

Clean up edges with a light skim or sharp blade

The beauty is that you’re not battling the material—polyurethane behaves itself and produces a tidy, functional component.

Because it’s one of those “save the day” materials. If you’ve got a length on the shelf, you’re never stuck waiting for a weird-size bush or resorting to a bodged solution.

I’d argue it’s as essential as keeping a stock of aluminium bar or mild steel in the corner—except polyurethane solves the kind of problems metal never can.

If you’re fed up with chasing parts that don’t exist, or you simply want the freedom to create exactly what your project needs, our Polyurethane Bar is the way to go.

Various sizes, proper automotive grade, and built to take real-world punishment.

Your project deserves a part that fits perfectly—so why settle for anything else?

What Do The Different Grades Mean?

If you’ve ever needed a part that simply doesn’t exist, this is your get-out-of-jail card. Our Polyurethane Bar is supplied in a range of diameters and lengths, giving anyone with a lathe the freedom to machine their own bushes, spacers, mounts, or whatever clever solution their project demands.

We use the same high-quality, extremely durable polyurethane that goes into our production bushes, so you’ll get the resilience, tear strength and longevity you’d expect—just in a raw, machinable form. Whether you’re restoring something obscure, building a one-off suspension setup, or solving a vibration issue the aftermarket hasn’t caught up with yet, this rod gives you the flexibility to create a proper, tailored component rather than bodging something that “sort of” fits.

If you ask us, it’s the perfect workshop staple: keep a length on the shelf, so you’ll always have a way out when an odd-sized bush crops up or you want to experiment with your own geometry.

It machines cleanly, holds tolerances nicely, and shrugs off the sort of punishment that would turn rubber to mush.

Ideal for:

Custom and prototype suspension bushes

Hard-to-find classic car parts

Spacer tubes, isolators, mounts and dampers

Anyone building something the parts catalogues forgot

Solid, dependable, and endlessly adaptable—exactly what you want when you’re making your own solution.

Fitment:

Accessories

Why Choose Polybush?

If you’re replacing tired, perished rubber bushes, Polybush polyurethane bushes are a smart long-term upgrade. Here’s why:

– Longer Lasting: Polybush bushes last significantly longer than standard rubber – they are resistant to oil, road grime, and age-related cracking.

– Improved Handling: Firmer than rubber, they reduce unwanted flex and improve steering response and stability, especially under cornering loads.

– Comfort Maintained: Engineered to retain OE ride comfort while improving feedback and control – ideal for fast-road, touring or heavy load conditions.

– No Grease Required: Unlike other polyurethane bushes, Polybush products are dry-fit, meaning no messy greasing or squeaking over time.

– Made in the UK: Manufactured to high tolerances in the UK using our unique polyurethane blend.

Key Benefits at a Glance:

– Direct replacement for your original suspension bushes.

– Sold as a full vehicle set – No need to buy multiple sets

– Maintains comfort while improving drivability

– Resistant to wear, chemicals, oil, UV, and weather – perfect for daily drivers and performance builds alike

– Backed by the Polybush reputation for quality. ISO:9001

Ideal for:

– Daily Driven Vehicles looking to maintain or restore OE comfort and performance

– Fast Road or Lightly Modified Cars needing better control without sacrificing ride quality

– Classic or Older Models where OE rubber has degraded or split

– Fleet, Commercial, or 4×4 Vehicles needing durable and consistent suspension performance

Upgrade your bushes today with Polybush – A long-lasting, British-made solution for sharper handling and reliable comfort.

– In Stock – Fast Dispatch

– Trusted UK Manufacturer – Polybush