28 January 2026

Speak to one of our experts.

2 February 2026

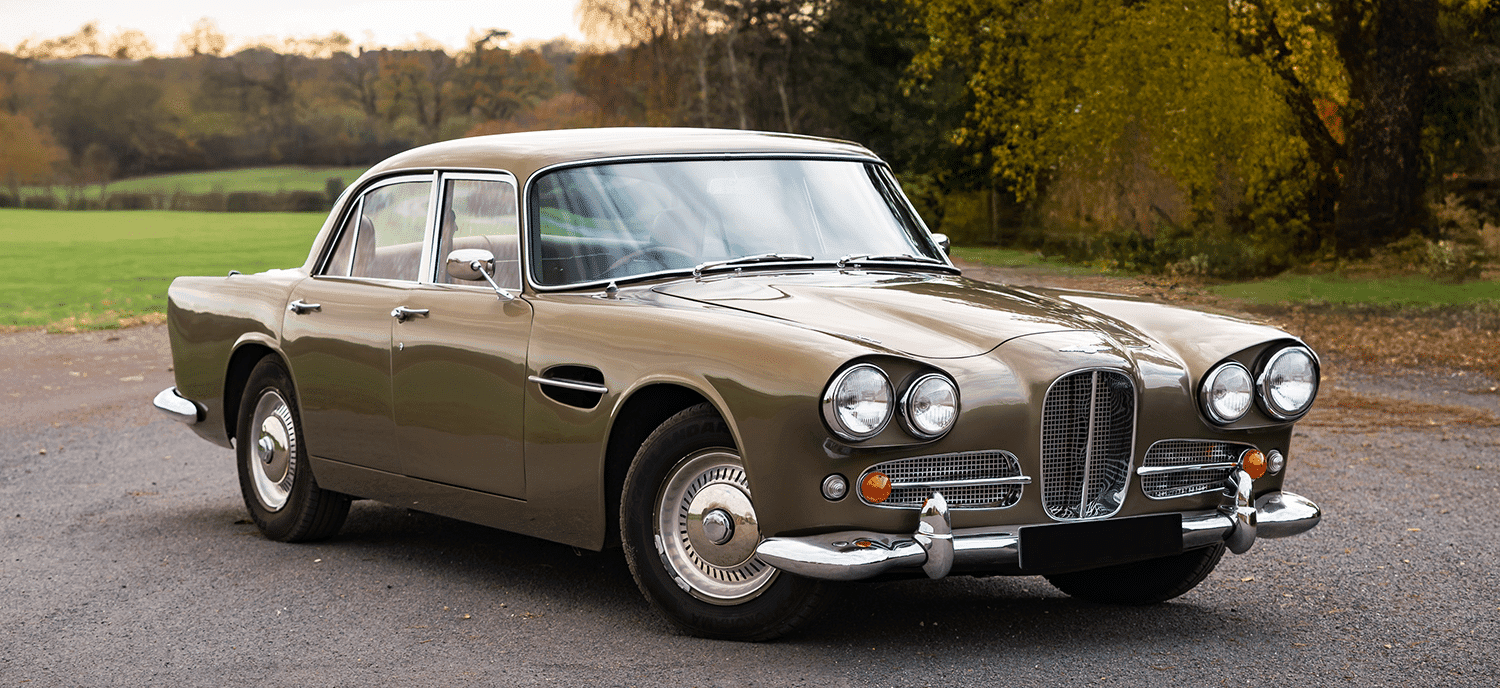

When Aston Martin Works Ltd get in touch, you know the brief won’t be about volume – it’ll be about getting things right.

That was exactly the case when Aston Martin Works contacted us to discuss custom-manufactured suspension bushes for one of the rarest cars ever to leave Newport Pagnell: the Lagonda Rapide.

Only 55 Lagonda Rapides were ever made, and it’s believed that just 49 remain on the road today. This isn’t a car you experiment on, and it certainly isn’t one where “near enough” will do. Aston Martin weren’t looking for quantity. They were looking for quality, accuracy, and longevity – which is precisely why they came to Polybush.

As a long-standing British manufacturer of polyurethane suspension bushes, we’ve been synonymous with polyurethane for over four decades. In fact, we believed in it so strongly that we trademarked the Polybush name over 40 years ago. It’s not just what we do – it’s what we’re known for.

The goal from Aston Martin Works was clear:

Produce bushes for the Lagonda Rapide that were as close to OEM specification as possible, while benefiting from the inherent advantages of modern polyurethane.

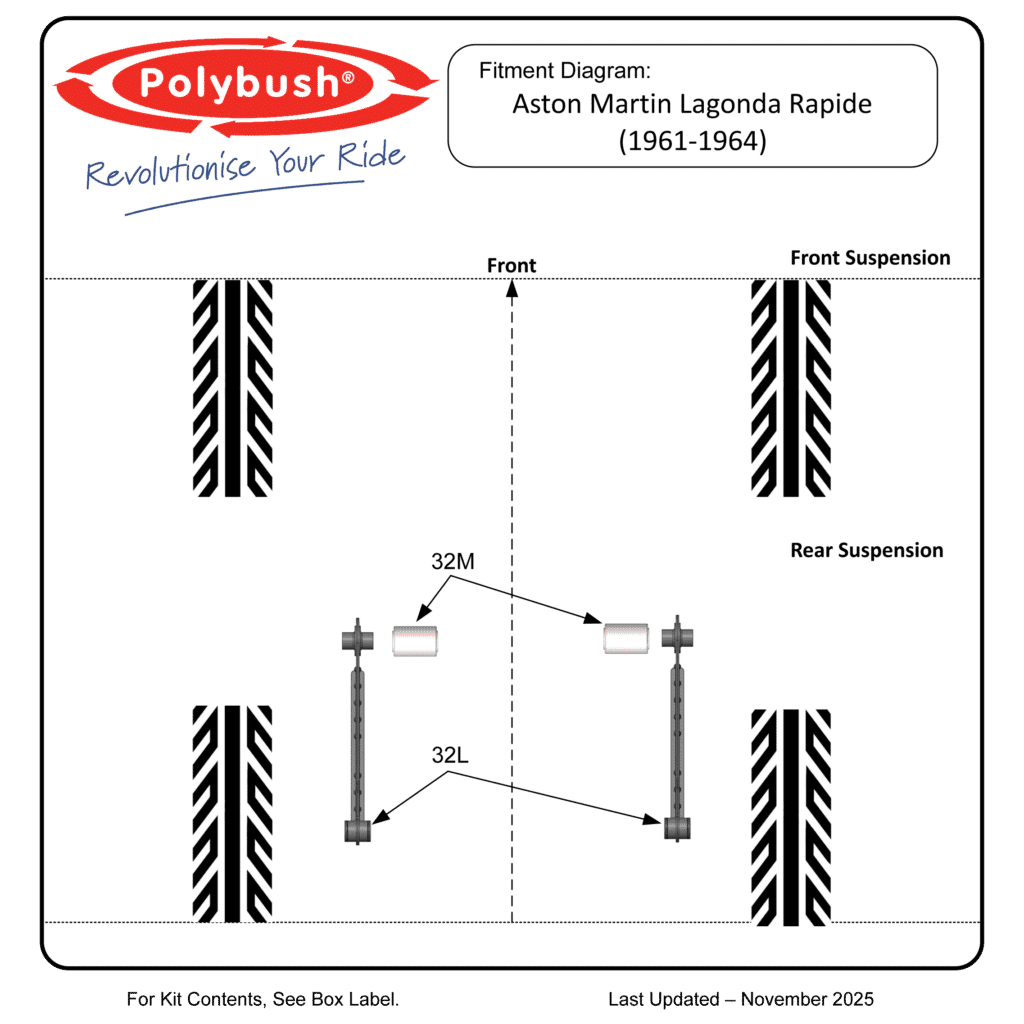

To achieve that, Aston Martin supplied us with original factory bushes and detailed dimensions. Working closely with their Chief Parts Advisor, our design engineer, Greg, meticulously benchmarked each original bush.

This process isn’t guesswork. Every critical dimension, void, bond and compliance characteristic was measured and analysed. The result was the ability to faithfully replicate the original behaviour of the suspension – not just how it fits, but how it feels on the road.

For a car like the Lagonda Rapide, that matters. Owners expect not only performance and stability, but also the comfort and refinement befitting an Aston Martin.

The project involved the development of:

A double-bonded suspension bush

A bespoke radius arm bush

Both were engineered specifically for this application and produced as a low-volume, high-end product, exclusively for Aston Martin Works Ltd. Once fitted, the feedback spoke for itself:

“Thank you for sending the bushes. I’m very pleased to report our technician has fitted them with no issues and the car is back on its wheels and mobile.”

That’s always what you want to hear – especially when dealing with something this rare.

Given the uniqueness of the Lagonda Rapide and the bespoke nature of the bushes, we agreed that these parts would be:

Exclusively produced for Aston Martin Works Ltd

Unavailable for direct purchase from Polybush

Instead, Aston Martin Works are listed as the official supplier of these components. It’s a sensible arrangement that protects the integrity of the vehicle, while increasing exposure for both companies – and it ensures customers get the right part, from the right source. You can purchase these parts directly HERE

Projects like this perfectly demonstrate what Polybush does best.

Our development team can design and manufacture custom polyurethane bushes for:

Low-volume production vehicles

Classic and heritage models

Specialist and performance applications

Whether the priority is comfort, longevity, precision, or outright performance, polyurethane allows us to engineer those characteristics into the bush from the outset – rather than compromising with a one-size-fits-all solution.

Traditional rubber bushes have their place, but they also have limitations:

Rubber degrades with age, oil, heat and ozone

Compliance changes over time

Dimensional accuracy can be inconsistent

By contrast, polyurethane suspension bushes offer:

Far greater resistance to wear and environmental damage

Consistent performance over time

The ability to fine-tune stiffness and compliance for the application

Improved steering precision and suspension control

Crucially for cars like the Lagonda Rapide, polyurethane can be engineered to deliver comfort as well as control – it’s not just about stiffness.

All Polybush products are hand-cast in the UK, allowing us total control over materials, quality, and consistency. For specialist projects, this approach is invaluable.

It means:

Tighter tolerances

Better bonding

Proper quality control at every stage

The flexibility to manufacture genuinely bespoke components

It’s also why manufacturers like Aston Martin Works trust us with rare, irreplaceable vehicles.

Working with Aston Martin Works Ltd on the Lagonda Rapide has been a genuine privilege. It’s a perfect example of how traditional British engineering, modern materials, and careful development can come together to preserve some of the finest cars ever made.

If you’re responsible for maintaining or developing a low-volume, classic, or specialist vehicle, and need suspension bushes engineered properly – not just adapted – that’s exactly where Polybush excels. Contact us on 01978 664316

To see the other Aston Martin’s – Click Here