REVOLUTIONISE YOUR RIDE

We Are The World Leaders In Polyurethane Suspension Bushes & Components For Both Cars & Vans.

What’s New?

Main Failure Bush For:

Juke Mk1, Leaf, Nv200, Pulsar,

X-Trail MK2&3 – Koleos Mk1&2

ISO9001 Certified

Now ISO9001 accredited, guaranteeing quality and performance in every product.

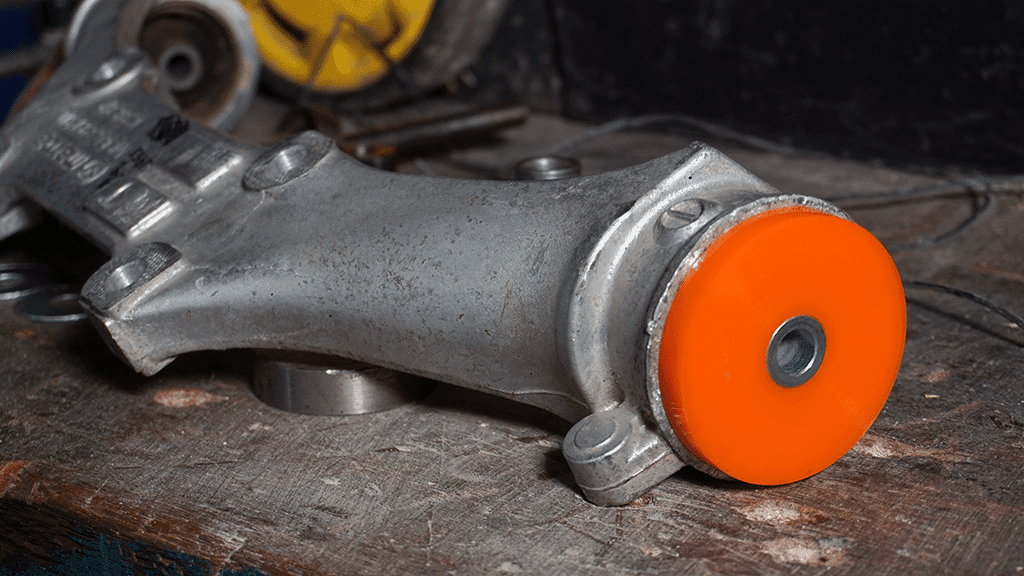

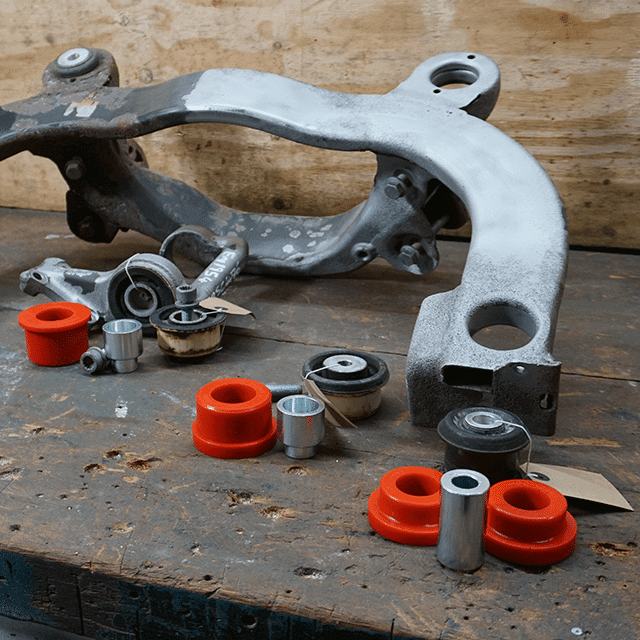

Why Fit Polybush

Fit Polybush for durability, improved handling, comfort, and long-lasting performance.

Suspension Bushes – Car, Van Commercial Vehicle or Bus

Find parts that match your vehicle.

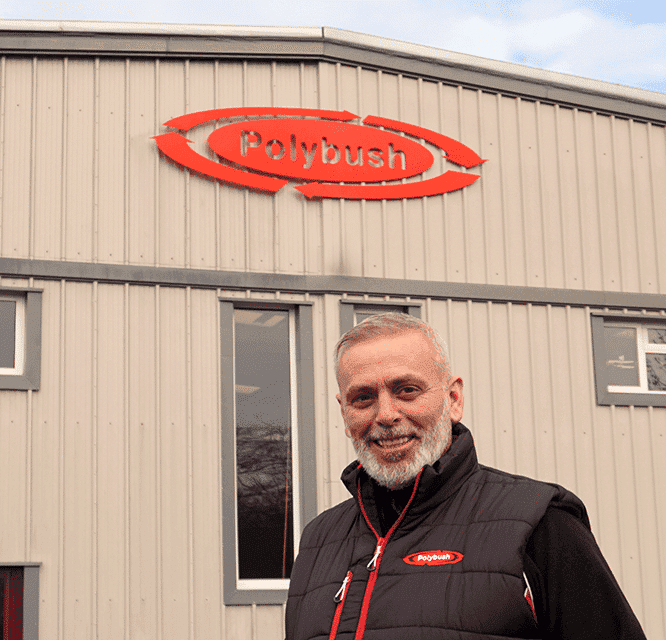

Polybush Achieves ISO9001 Accreditation.

At Polybush, we always pride ourselves on the precision and care that goes into manufacturing our polyurethane suspension bushes. Achieving ISO9001 accreditation validates these efforts, proving that we operate to the highest quality management standards. From the design and production process to customer service and internal operations, this certification highlights our dedication to continual improvement and efficiency.

Mark Burgess

Mr. O’Neill

Parts are quality items, competitively priced.

Jeff Fielding

I have a Mk2 Golf and i’ve used this product on almost every part of the car It’s a quality item at a great price

Stephen Coy

Prompt & Efficient Service.

Julian Annells

Easy to find what I wanted. Fast Dispatch!

31BD – Steering is tighter but no increase in noise or vibration at all. Very happy.

I ordered a set of bushes for the lower front (banana) arms on my Jaguar XF. Very straightforward to fit. Could feel the difference immediately compared to the worn OEM bushes. Steering is tighter but no increase in noise or vibration at all. Very happy.

A great company !

A great company, having watched a video by LR Parts, I realised Polybush were based on North Wales and only a 10 min drive from me. I found Ellis to be really helpful, offering really helpful advice. They now do a click and collect service, which I find very useful. I will be back for more bushes.

Mr Michael James

I went on the website, found the items I wanted and completed the order by 11.30 am, It arrived by 13.30 the next day awesome service! I will definitely be using you again!!

Peter Crisp

Great Product & Service.

Peter Marsden

The product arrived quickly and most importantly fixed my issue. The rattle from the rear springs has disappeared. I am so happy as it was very annoying!

Robert Jones

Great to deal with and Polybushes have made the world of difference in comfort to my Defender

Paul Pardington

This is the second lot I’ve put on my car, which has now done over 200k. They’re much better than standard bushes.

Rust & oil

1st time I’ve bought directly from Polybush….. Impressed

Mark Southgate

Great product I have used them a lot and always fast despatch

Justin Muers

Due to a mail strike the product arrived later than I wanted it to, BUT, that is not the fault of Polybush. I love the product and look forward to my next opportunity to install their bushes in my vehicles.

Ryan Dunn

Always been happy with Polybush. Never disappointed.

Changed to another brand once that was allegedly better. Load of nonsense. Didn’t last a year on the racecar. Back on Polybush, 2yrs passed and haven’t looked back

Nathan Gibson

Great product, good customer service. Used on my fiesta time attack car with no issues. Very happy with them

Graham C

All bushes on my Land Rover Defender (1995) have now been replaced with Poybushes. The effect is a noticable drop in road noise being transferred to the cab. The handling and ride is now smoother. When they need replacing many years hence, that will be a lot easier than getting the old standard bushes out!

Richard Neath

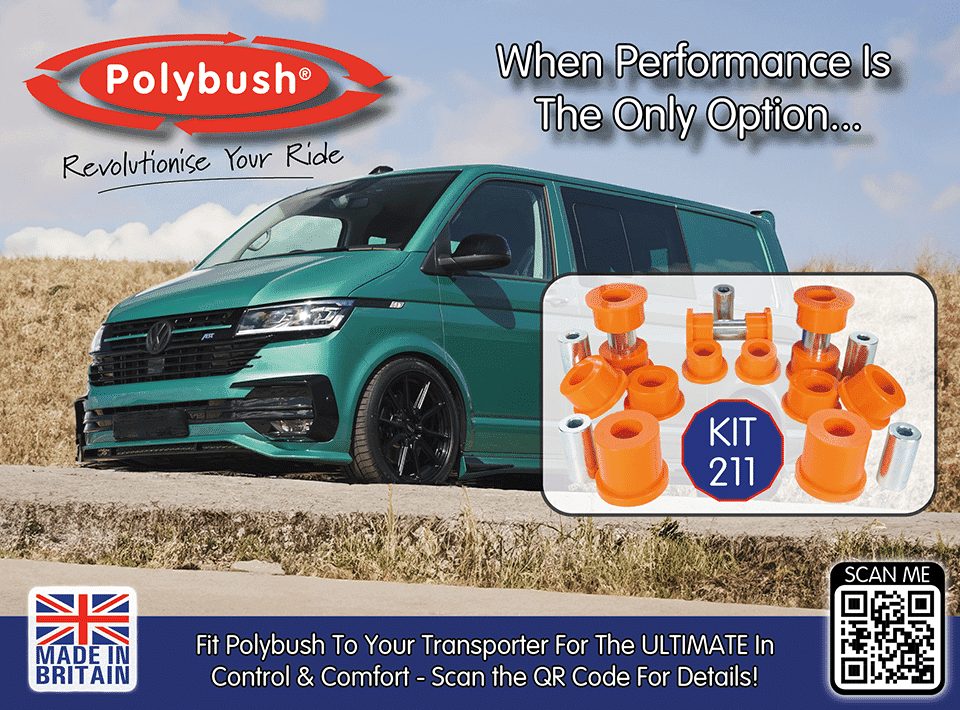

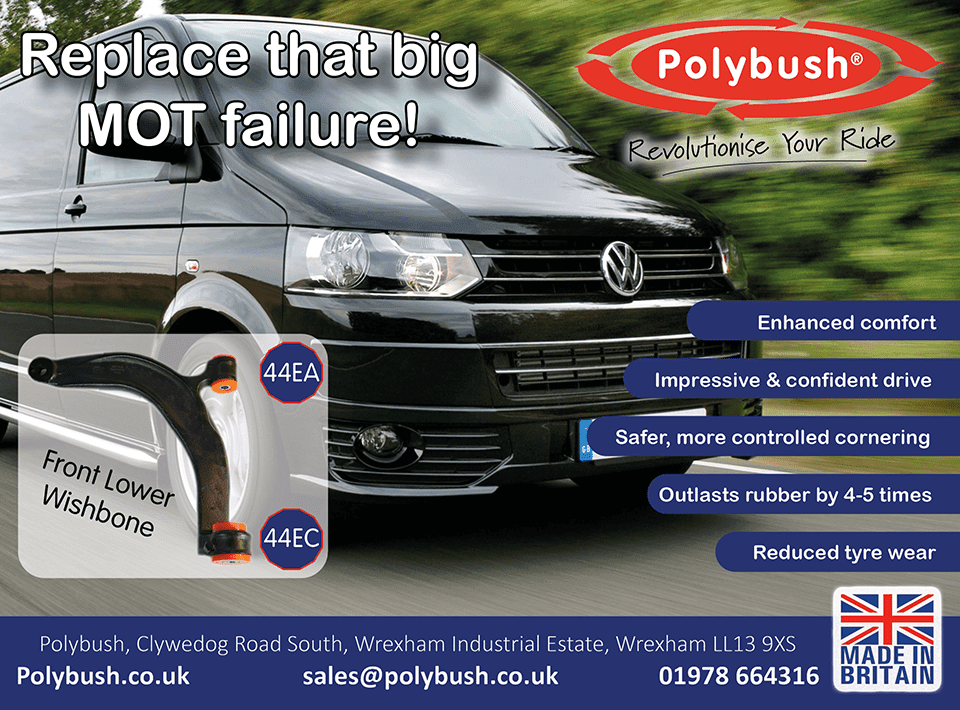

Full set of bushes fitted to my VW transporter. I can honestly say that the difference is utterly incredible. The pot-holed roads up here on Skye suddenly seem far less dreadful! The decrease in body-roll is really noticeable also.

Great service and so approachable. Polybush – a massive thank you.

Tony Manyvong

Would recommend definitely buying again, Even all the way from states!! Great quality and very easy to install on my 1990 Mazda Mx5 Miata.

Marcus M Blake

While all the pieces did not fit for my vehicle – stabilizer bar ends for my L200 K34T GJENTUR – everything else did, front and rear. It has been two years since the installation, and they are still in good condition with tons of off-road km under them and what looks like tons more to go (If allowed, 4.5 Stars)

I STRONGLY recommend products from PolyBush.

Richard Neath

I ordered a full set of bushes fitted to my VW transporter. I can honestly say that the difference is utterly incredible, the potholed roads up here on Skye suddenly seem far less dreadful!

The decrease in body roll is also really noticeable. Polybush, you provide great service and are so approachable. A massive thank you!

Pete Calkin

A big difference right out of the box. The van feels tighter and more direct without feeling harsh.

Everything just feels ‘newer’ in terms of ride quality and driving feel.

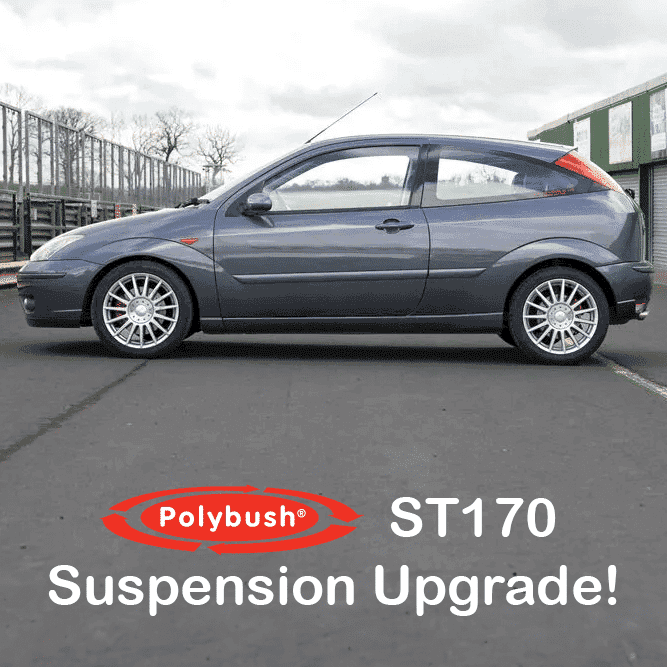

Fiesta ST150 Race Series

Since fitting the Polybush bushes to our Fiesta ST150 race cars the handling has been vastly improved, lap times have also dropped and the cars are far more driveable.

Choose Your Vehicle. We’ve got what your looking for.

Need help? Speak to our experts

Need help? Speak to our experts

Abarth

Accessories For

Alfa Romeo

Aston Martin

Audi

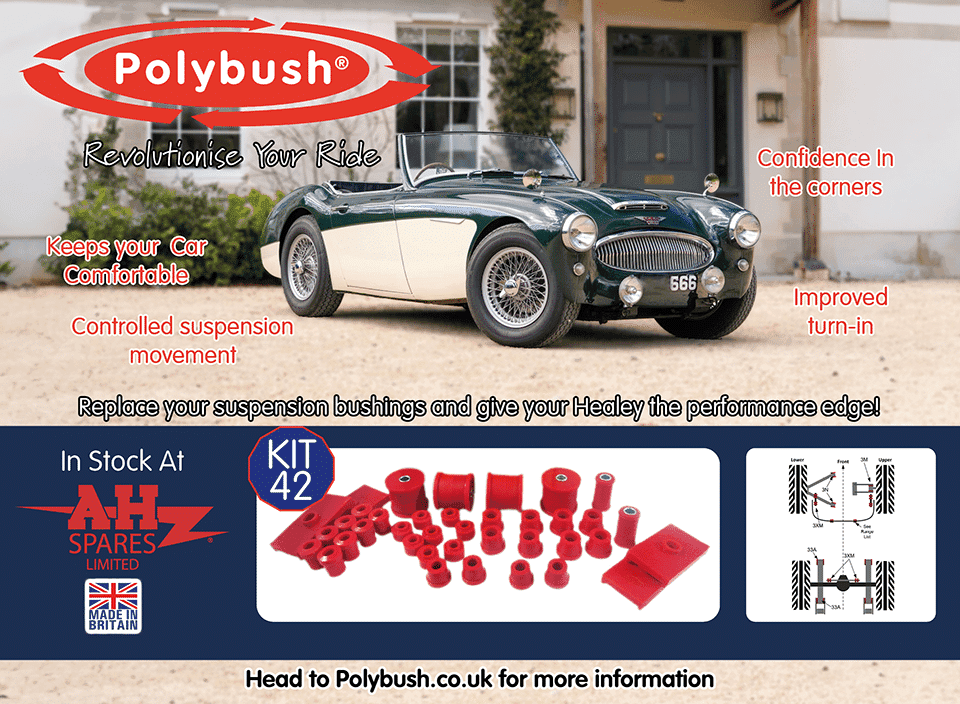

Austin Healey

Bedford

BMW

Chrysler

Citroen

DAF

Daimler

Dodge

DS

Fiat

Fisker

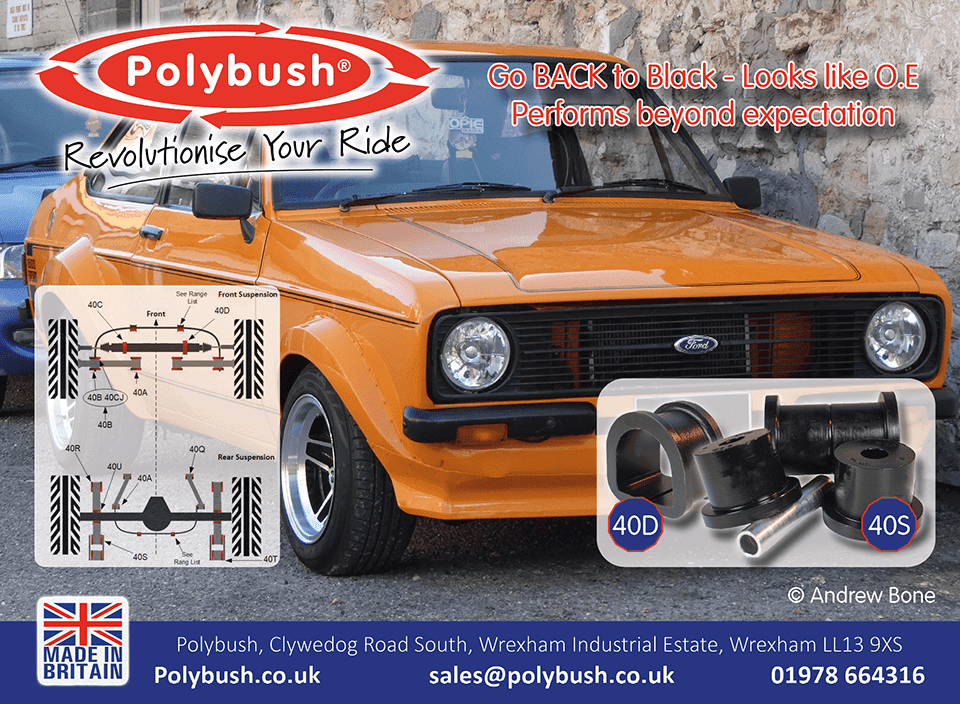

Ford

Honda

Hyundai

Isuzu

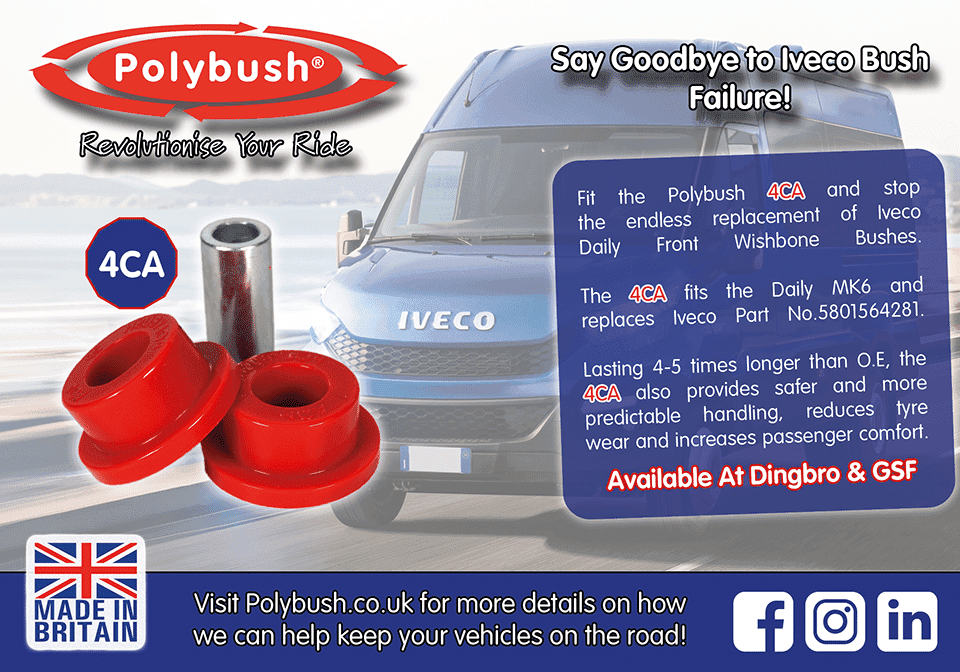

Iveco

Jaguar

Jeep

Kia

Lancia

Land Rover

LEVC

Lexus

Leyland

Lincoln

Lotus

MAN

Mazda

Mercedes

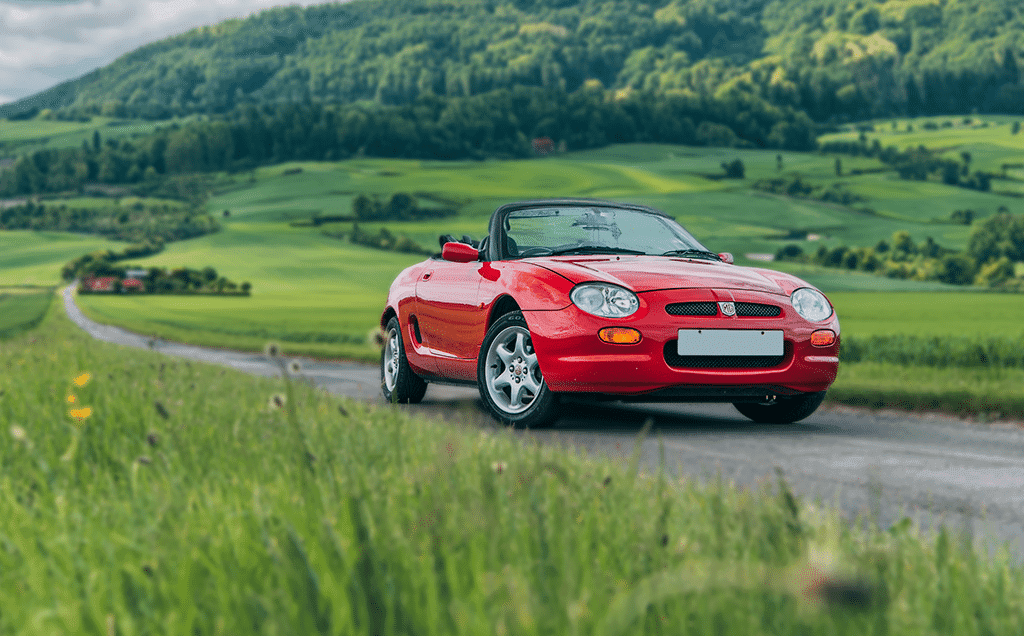

MG

Mini

Mitsubishi

Morris

Nissan

Opel

Optare

Peugeot

Porsche

Renault

Riley

Rover

Seat

Skoda

Smart

Subaru

Suzuki

Toyota

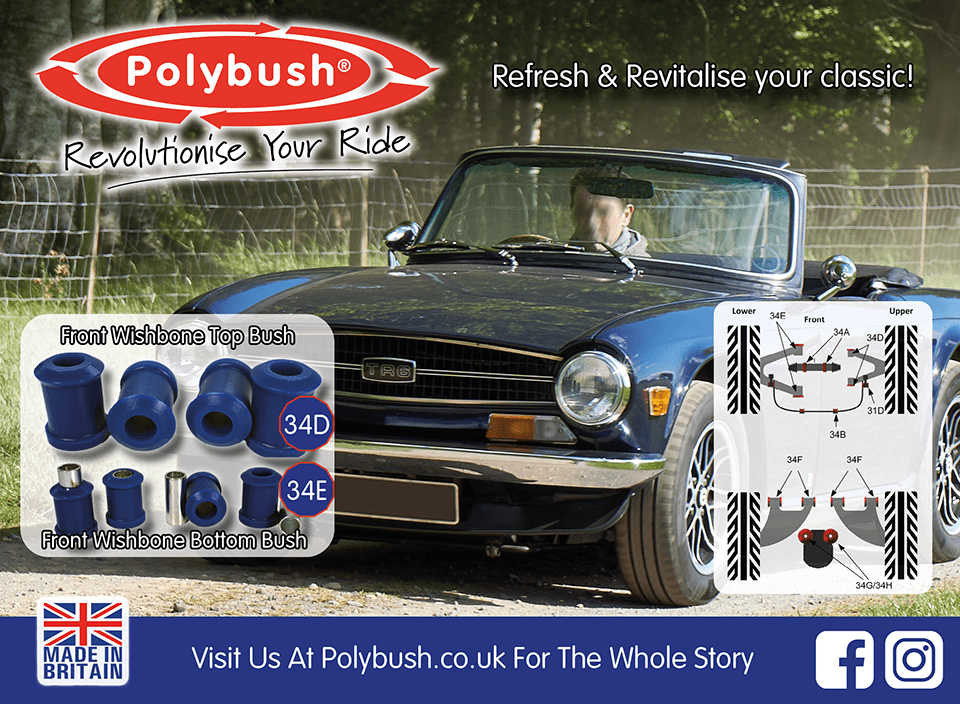

Triumph

TVR

Vauxhall

Volvo

VW

Wolseley

Wrightbus

Stay Up To Date with our latest news

Need help? Speak to our experts

Need help? Speak to our experts

21 May 2025

New Product Release: Polybush Suspension Bushes for Land Rover Defender 90, 110 & 130 (L663) (2020-Onwards)

1 May 2025

Stop the Downtime: Fit Polybush 55A to Your LEVC TX5 (TXE) and Keep Your Taxi Earning

28 April 2025

Behind the Scenes at Polybush: LR Centre Visits Our UK Facility

22 April 2025

How 40BR Solves Failing Rear Axle Bushes – Fiesta Mk7 ETC.

17 April 2025

Introducing the New 39X Rear Axle Bush – The Ultimate Polyurethane Rear Axle Bush Replacement

26 February 2025

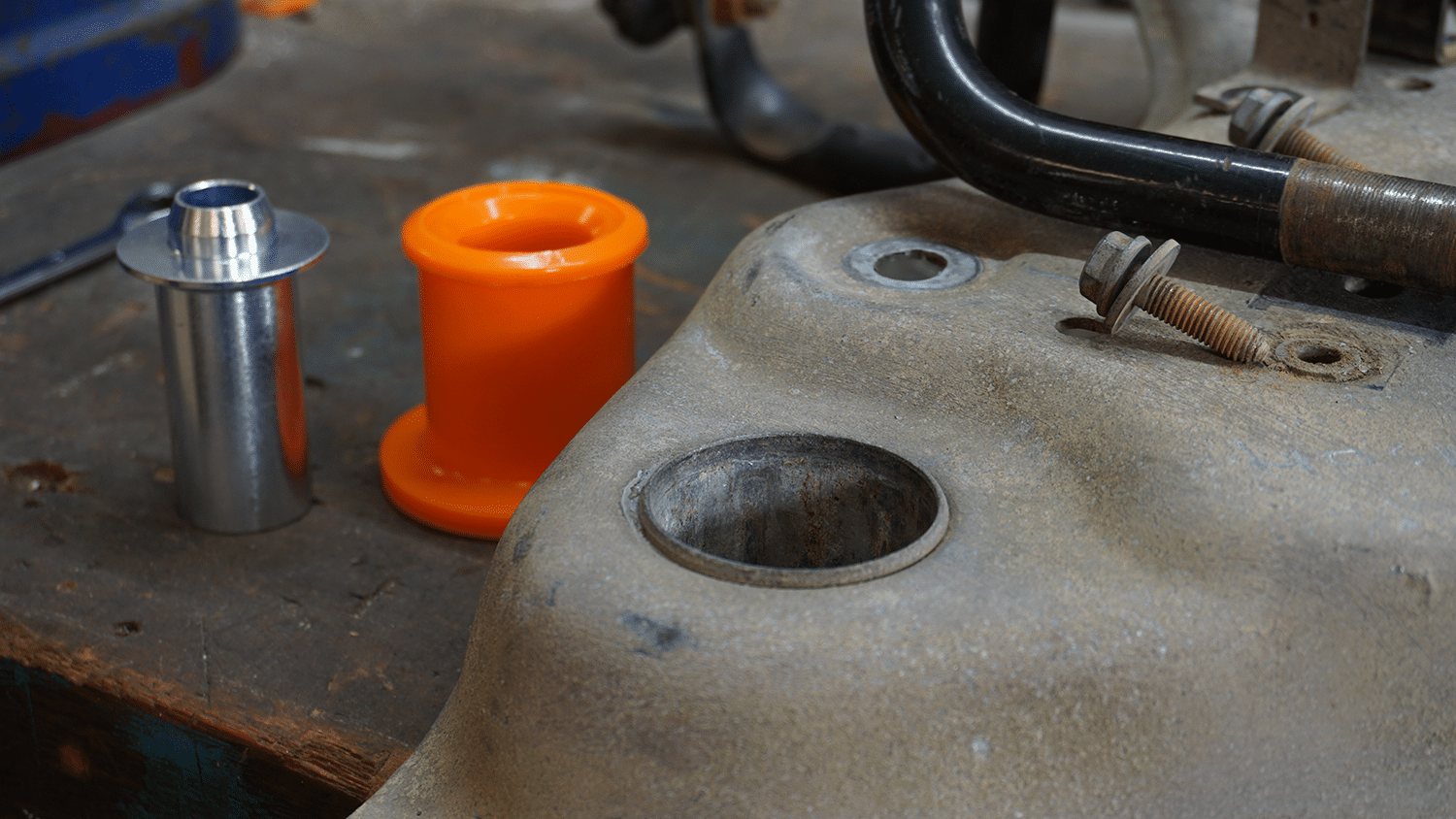

Ellis’s Guide to Transforming Your Mazda MX-5 with Polybush 27AS Door Bushings

24 January 2025

New Polyurethane Bushes for X-Trail, Juke, Leaf, and More!

Commercial, General, New Products, News

22 January 2025

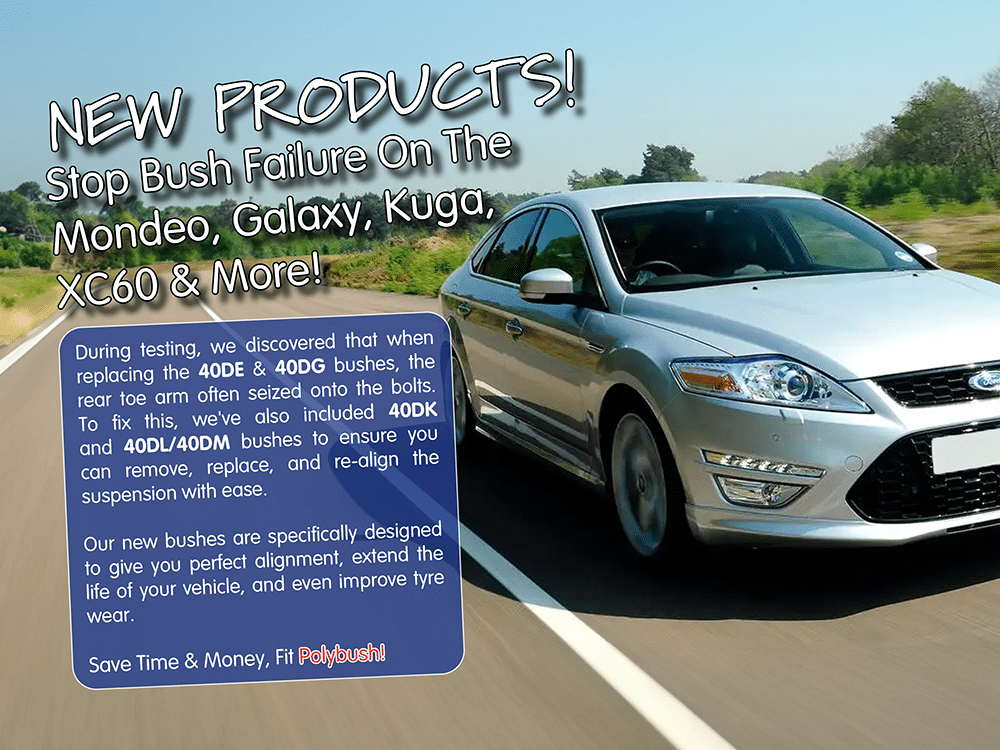

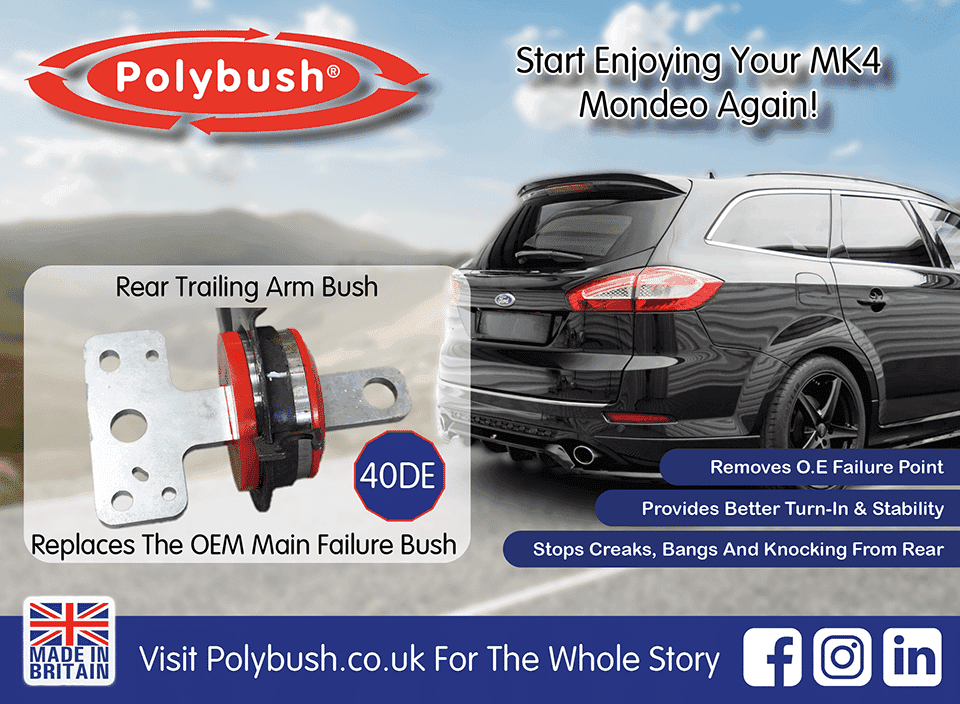

Upgrade Your XC60, Galaxy, Kuga, Mondeo, and More!

Commercial, General, New Products

9 January 2025

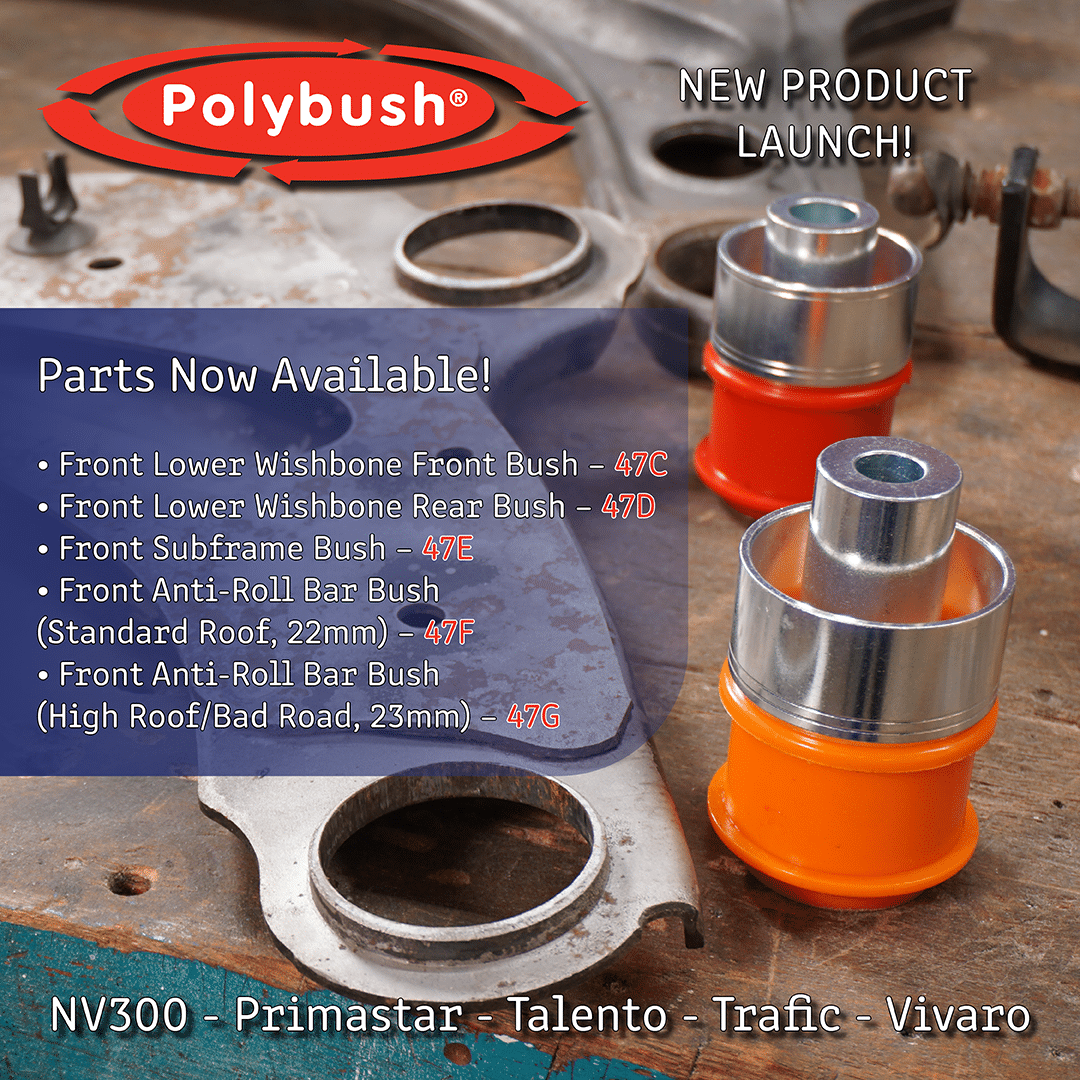

Stop Front End Knocking On Vivaro & Trafic – Subframe Bush Failure

3 December 2024

New Suspension Bush Range Released for Vivaro, Trafic & More.

27 November 2024

Why SUVs Are Tough on Suspension – and How Polybush Can Help

13 November 2024

Upgrade Your Toyota Celica ZZT230-ZZT231 with Polybush Kit 135

15 October 2024

Upgrade Your MX5 NC with Polybush 27AY Rear Diff Carrier Bushes

9 October 2024

Audi TT Differential Mounting Bushes & Rear Gearbox Support Bush

8 October 2024

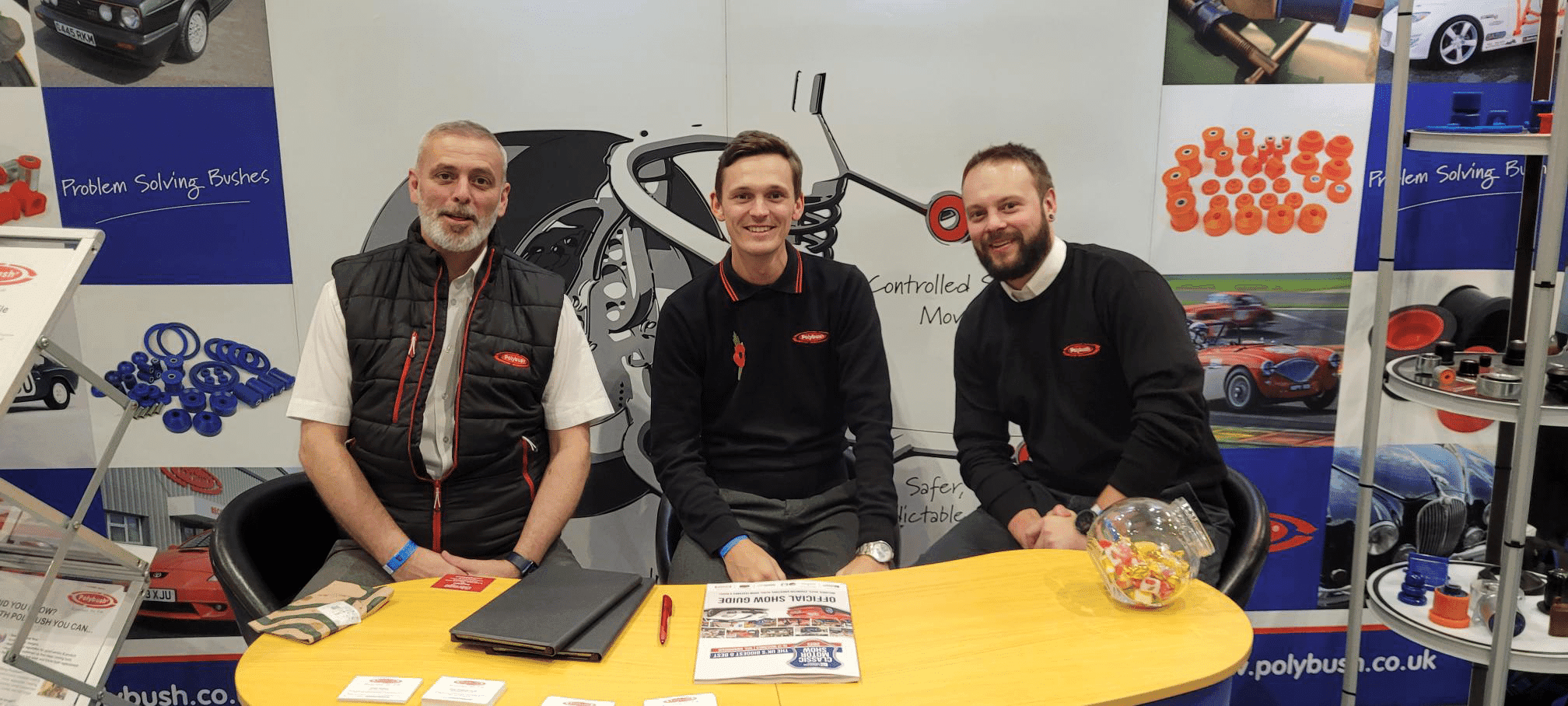

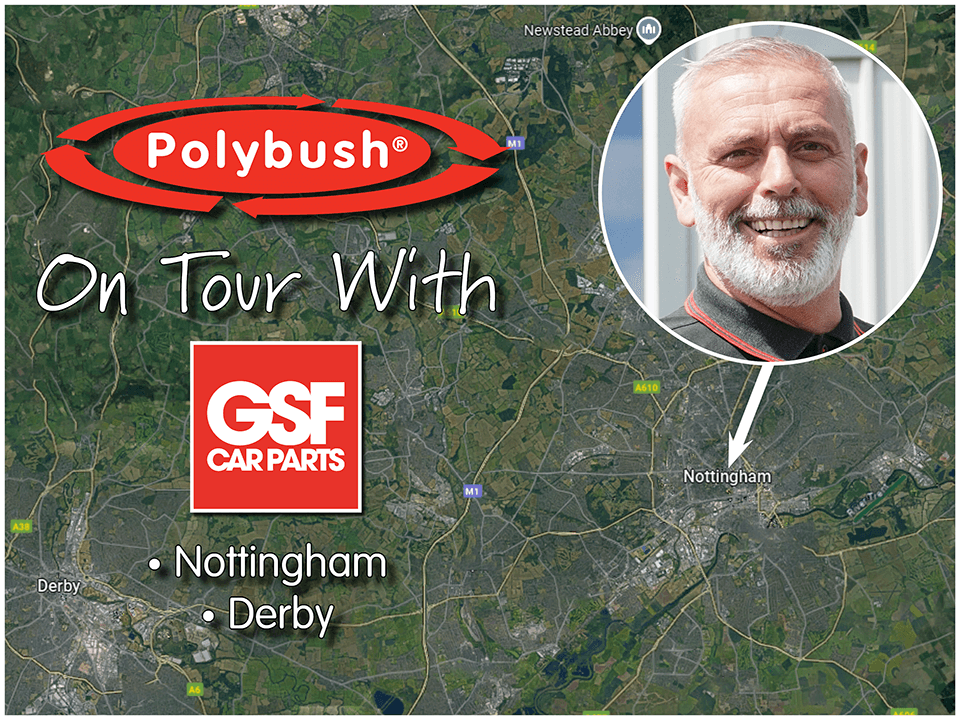

On The Road With Justin And GSF – Nottingham & Derby

7 October 2024

Polybush Achieves ISO9001 Accreditation – What It Means for Us

1 October 2024

Upgrade Your Audi, VW, SEAT, or Skoda with Polybush: The Best Polyurethane Suspension Bushes for Precision and Durability

24 September 2024

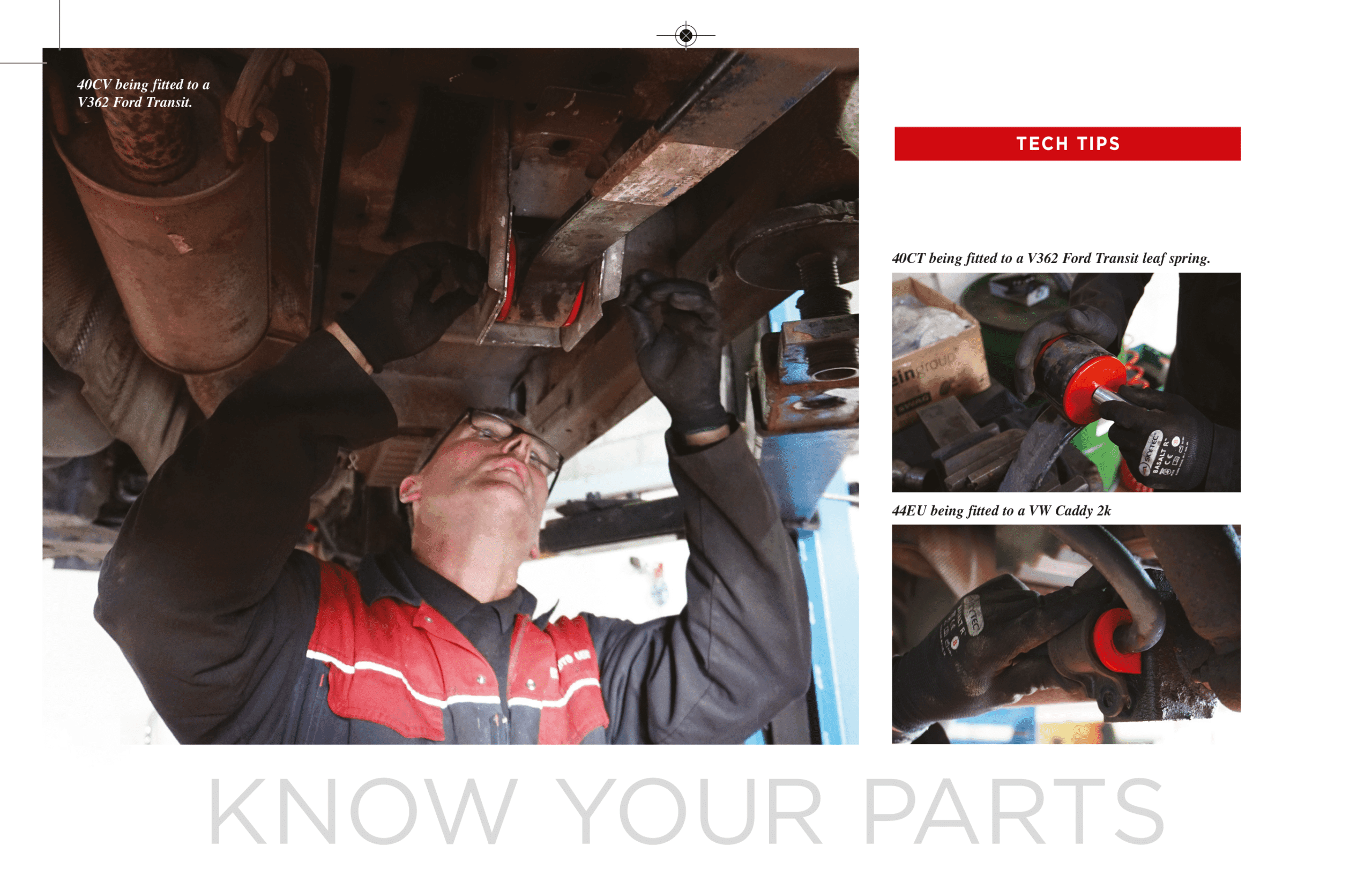

Transforming the Ride Quality of Excel Signs’ Ford Transit V362

27 August 2024

Justin’s Torquay Tour – August 28-29th

Advice Blog, Commercial, General

20 August 2024

Dispelling The Myths Behind Polyurethane Bushes.

Advice Blog, General, New Products

10 August 2024

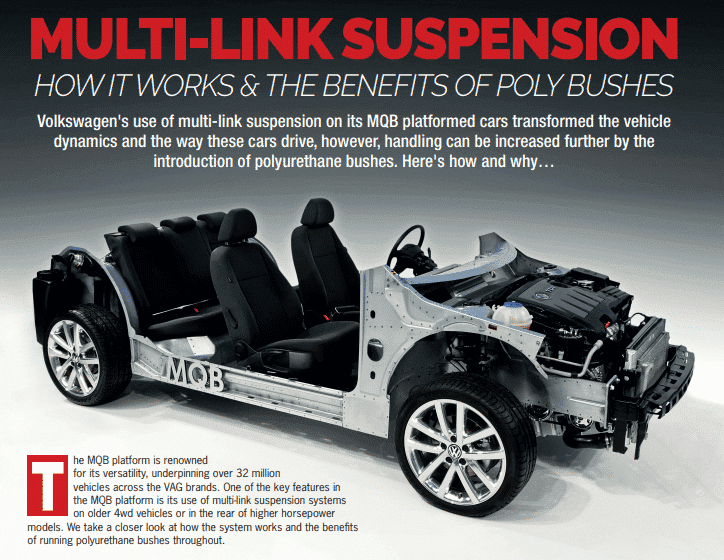

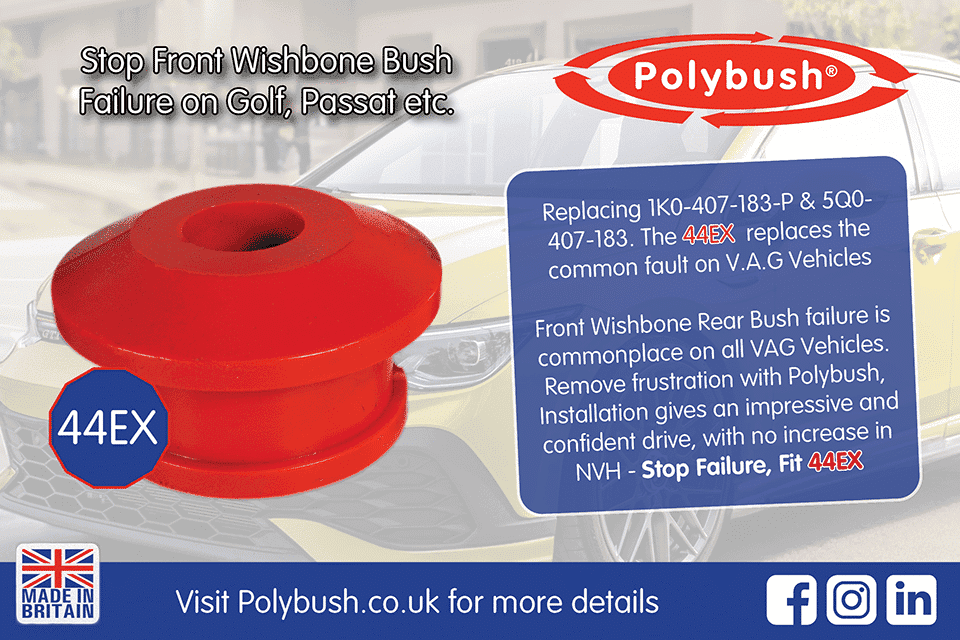

How Multi-Link Suspension Works on the V.A.G MQB Platform

9 August 2024

Polybush Keeps the Lancia Aurelia on the Road: A Customer Success Story

6 August 2024

On The Road With Justin And GSF – Hull – AGAIN!

31 July 2024

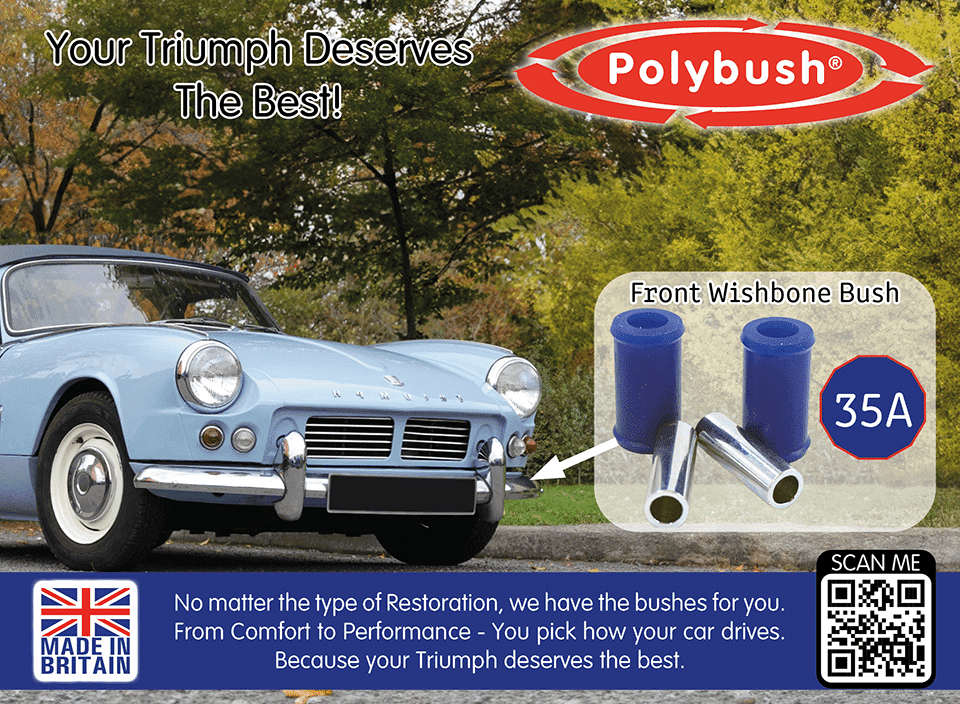

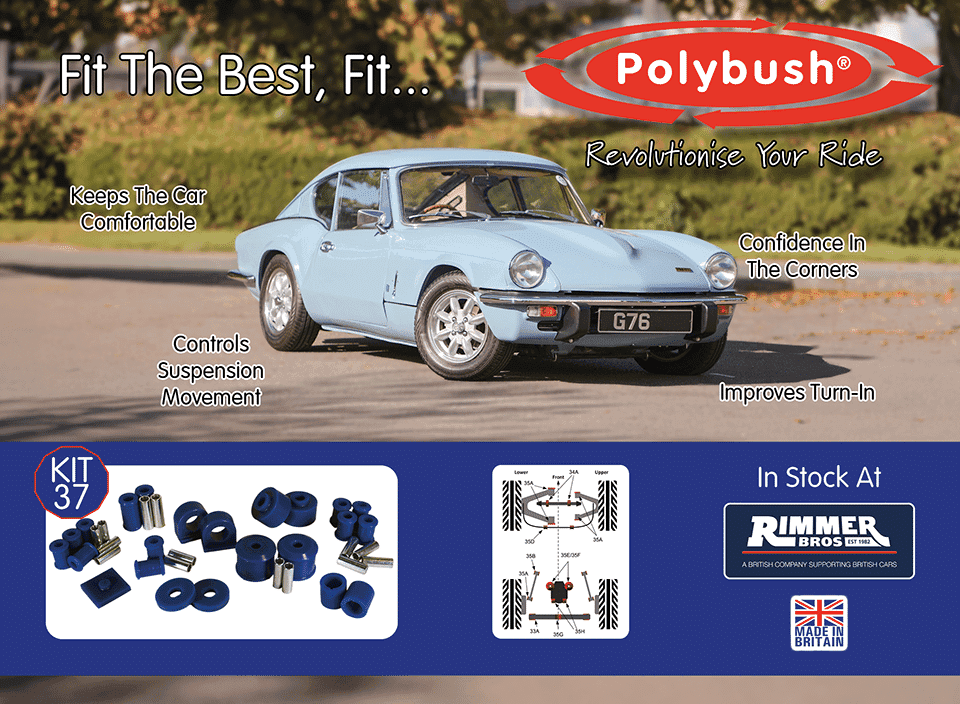

Upgrade your Triumph with Polybush’s 35A Front Wishbone Bush

30 July 2024

On The Road With Justin And GSF – Plymouth & Saltash

Advice Blog, Commercial, General

22 July 2024

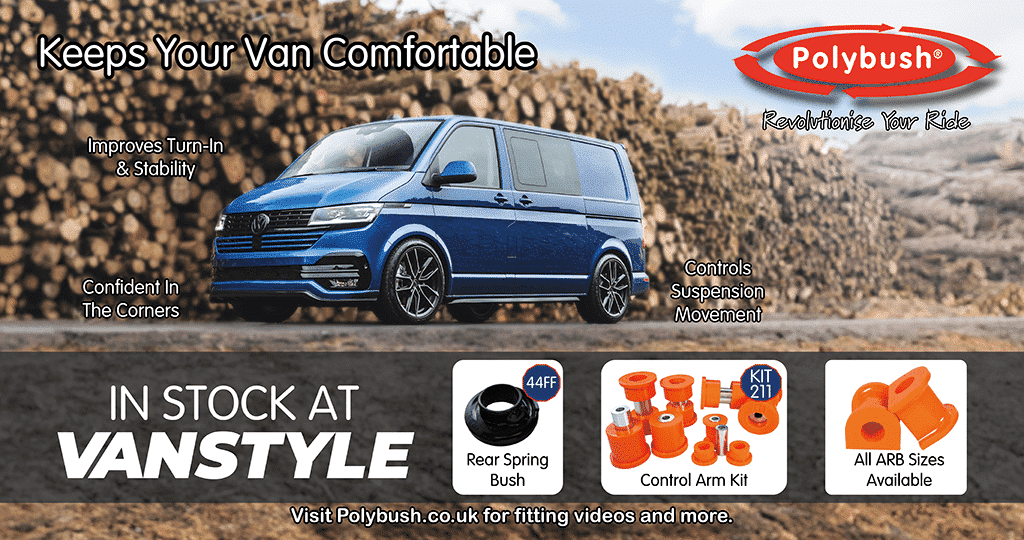

Why Polybush Kit 211 is the Ultimate VW T5 Suspension Upgrade

Advice Blog, Commercial, General

19 July 2024

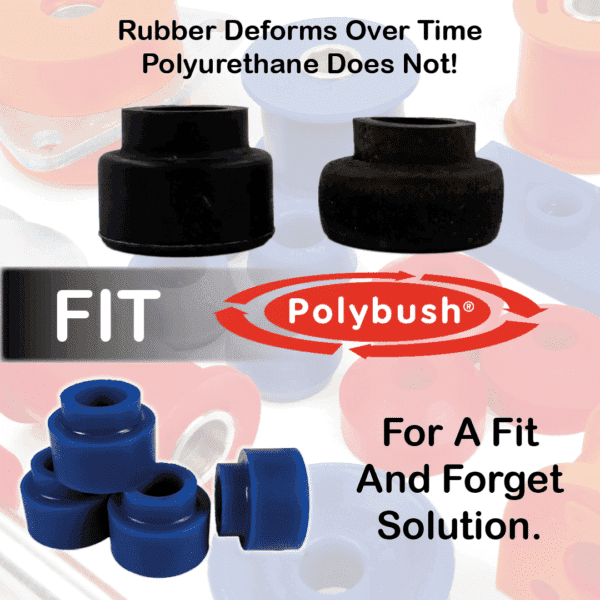

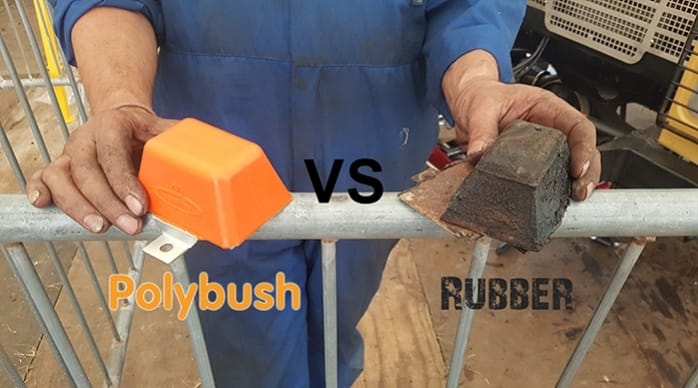

Don’t Fit Rubber, Fit Polybush

9 July 2024

On The Road With Justin And Dingbro – Dumbarton, Glasgow & Paisley

3 July 2024

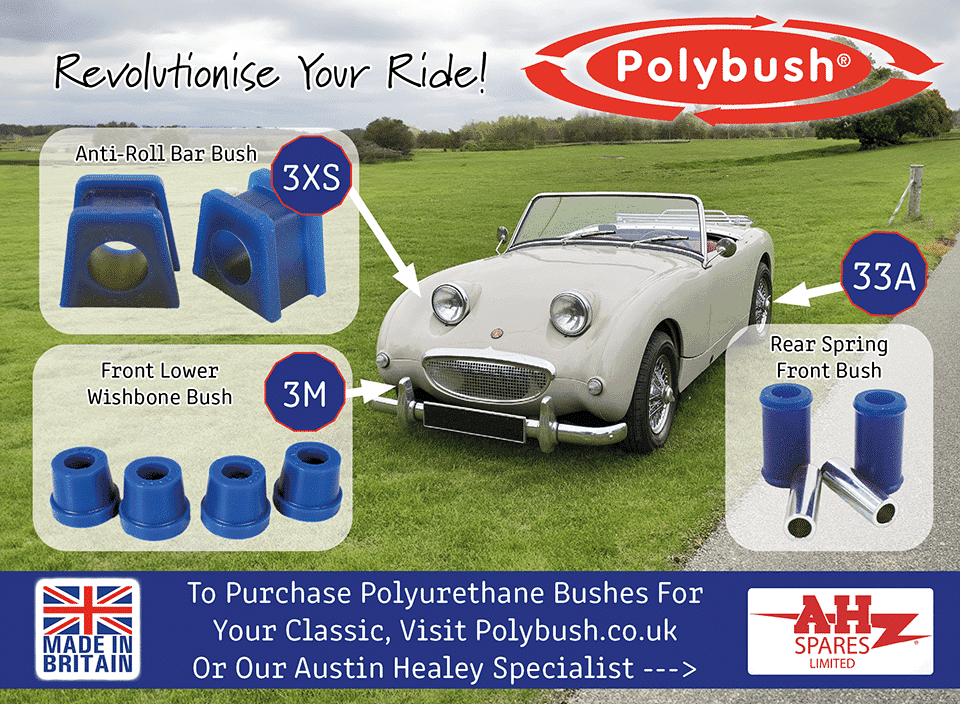

Ensuring Austin Healey Owners Are Well-Equipped with the Best Bushings: Our Partnership with AH Spares

25 June 2024

On The Road With Justin And GSF – Derby & Nottingham

18 June 2024

On The Road With Justin And GSF – Exeter & Torquay

Advice Blog, General, New Products

17 June 2024

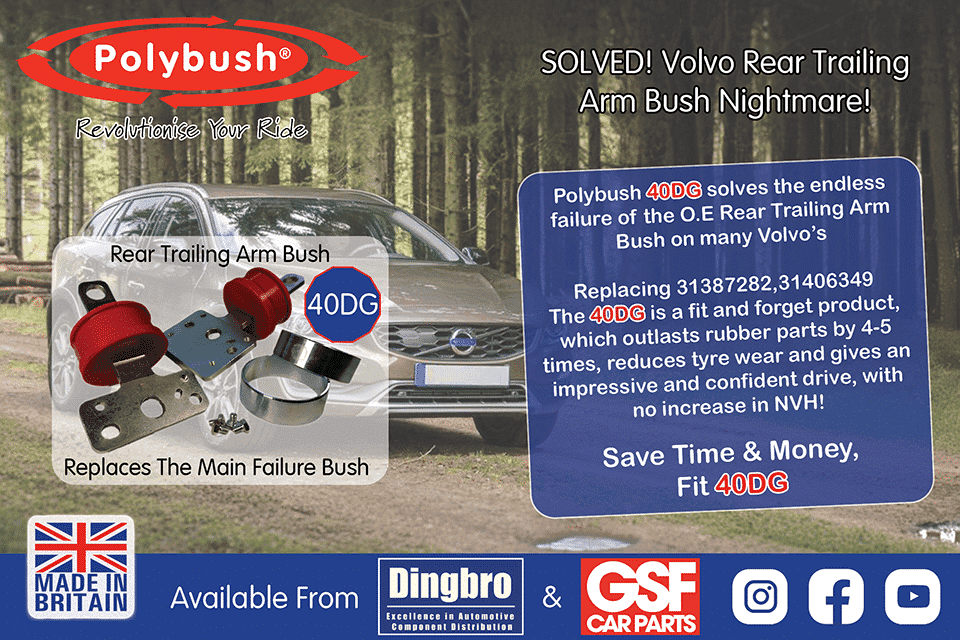

Polybush Introduces Trailing Arm Bushes for Ford and Volvo

10 June 2024

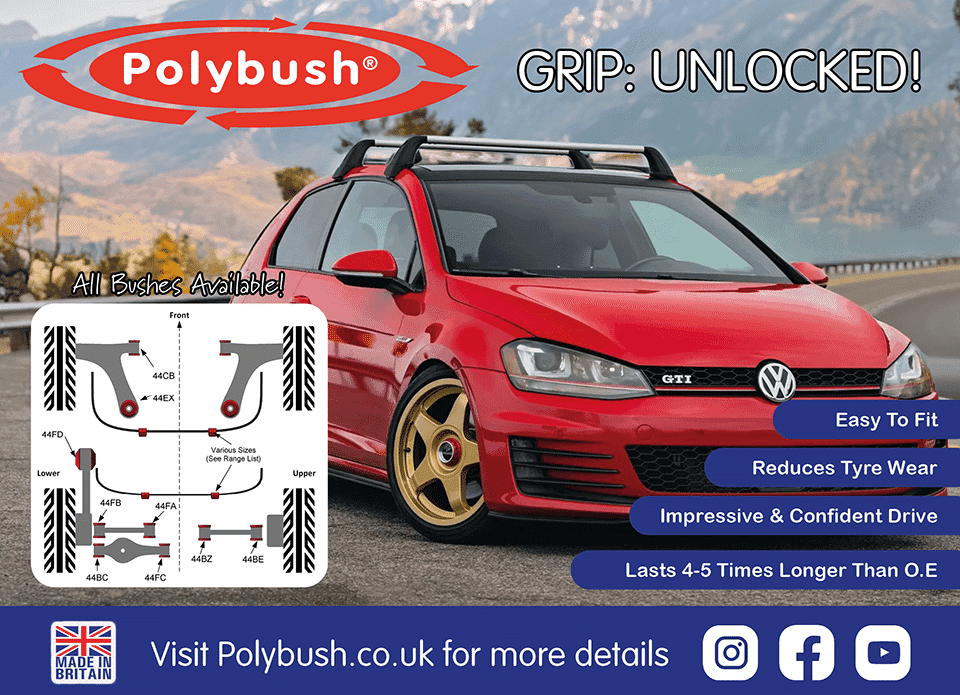

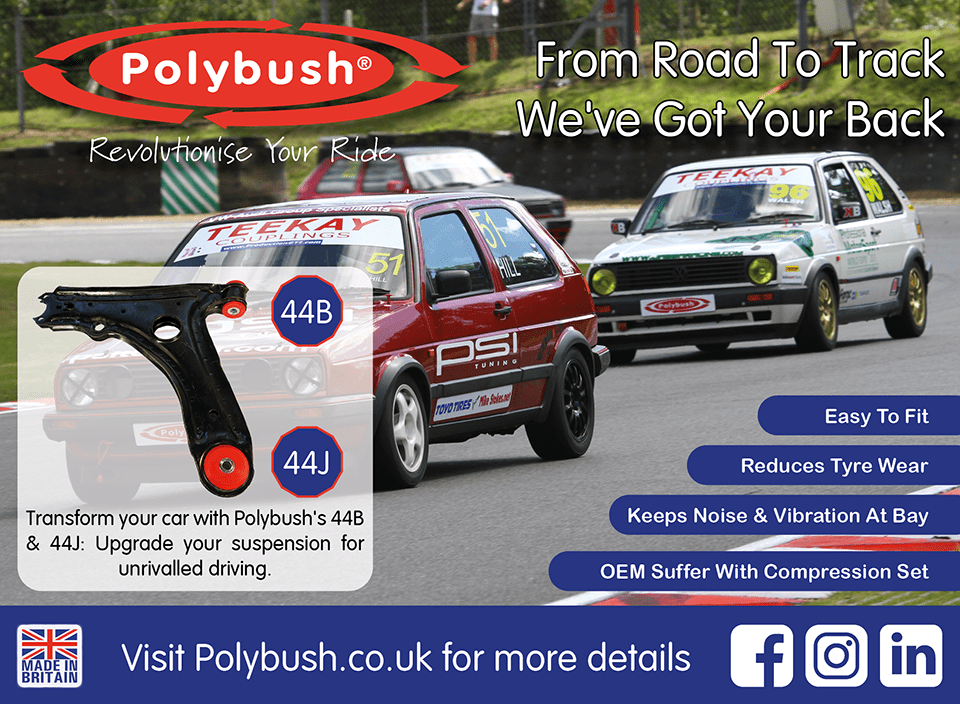

Transform Your VW Golf with Polybush: Unlock Grip and Improve Braking

5 June 2024

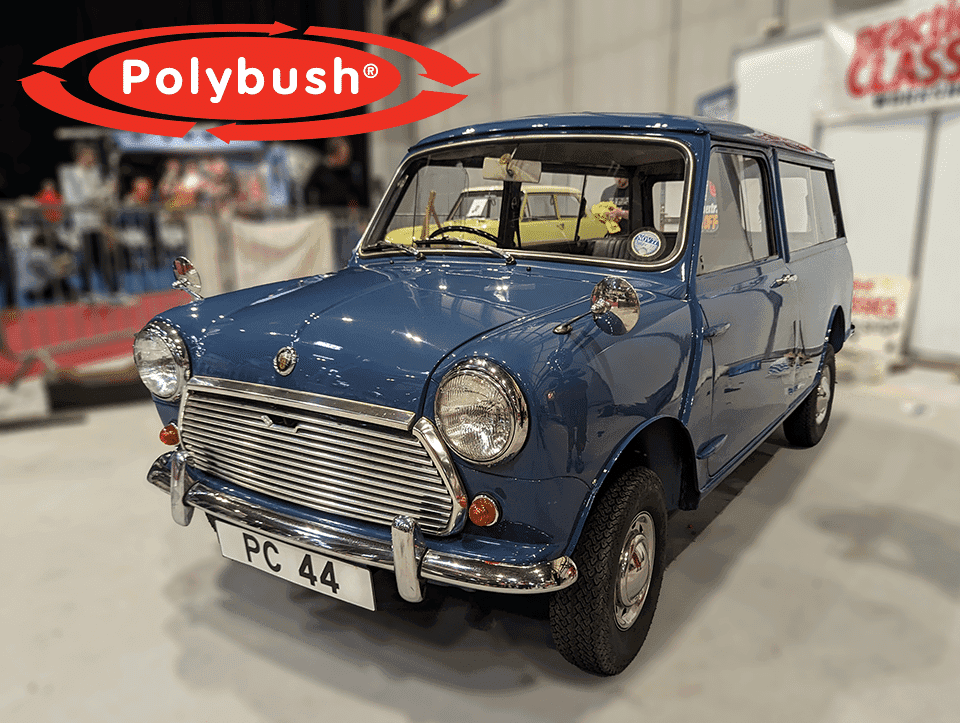

Preserve Tradition & Enhance Performance

31 May 2024

Why Should You Fit Polybush To Your MX5?

24 May 2024

On The Road With Justin And Dingbro – Fraserburgh, Peterhead, Elgin & Inverness

16 May 2024

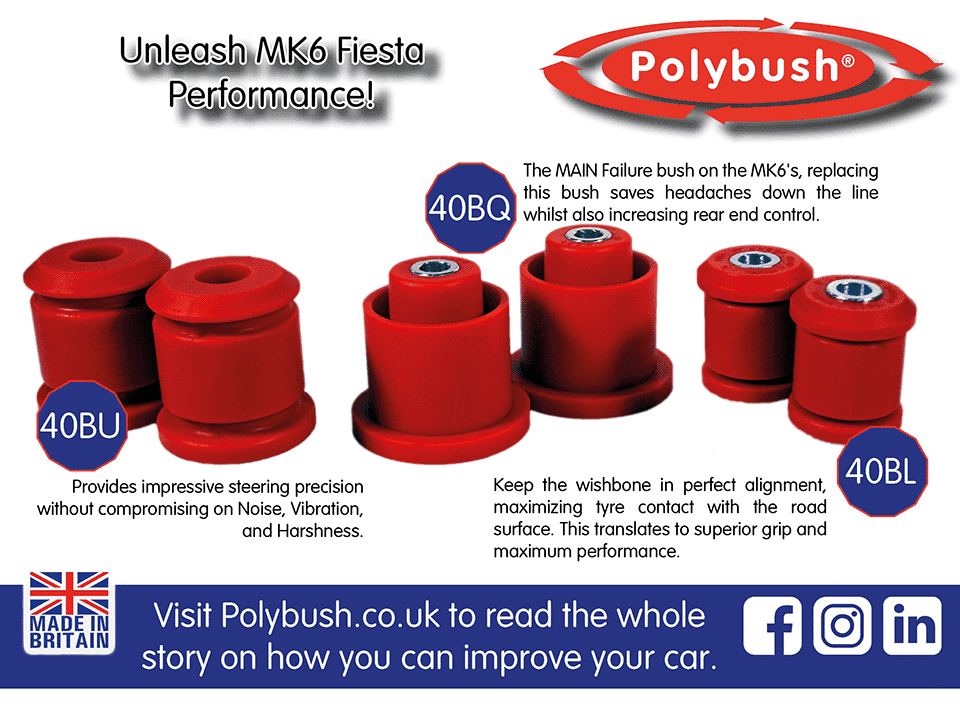

Unleashing the Potential of Your Ford Fiesta Mk6 with Polybush

8 May 2024

Preserving the Vintage Charm of Your MGB GT with Polybush

3 May 2024

On The Road (Again) with Justin and Dingbro.

24 April 2024

Perfecting Front Wishbone Performance for Ford Fiesta Mk6 with 40BU and 40BL

19 April 2024

Fast Car Mag Gets A Ford Focus ST170!

16 April 2024

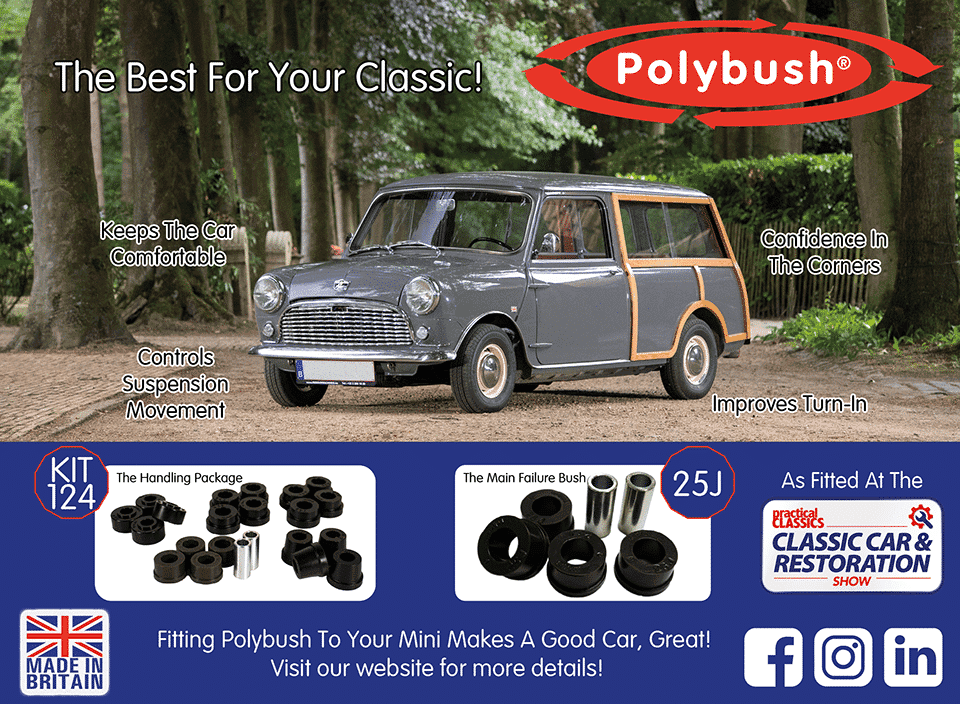

Reviving a Classic: Practical Classics Matt’s Journey with Polybush

8 April 2024

On The Road with Justin and Dingbro.

29 February 2024

Join Us at the Practical Classics Car and Restoration Show 2024!

28 February 2024

Two in the bush! – PMM FEB

26 February 2024

Polybush Joins the Restoration Journey of a Classic Mini MkII Countryman

23 February 2024

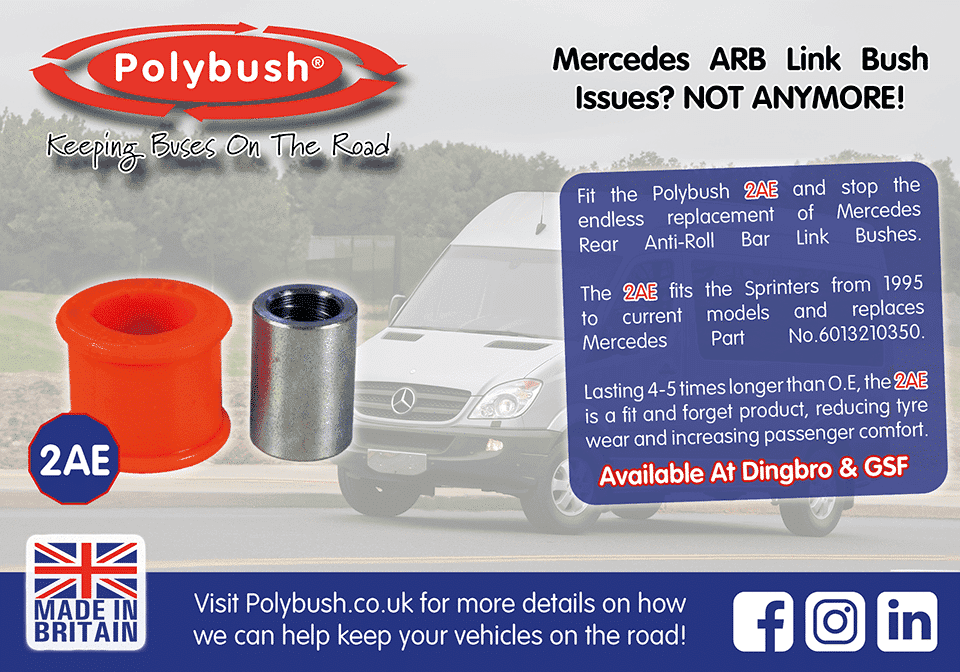

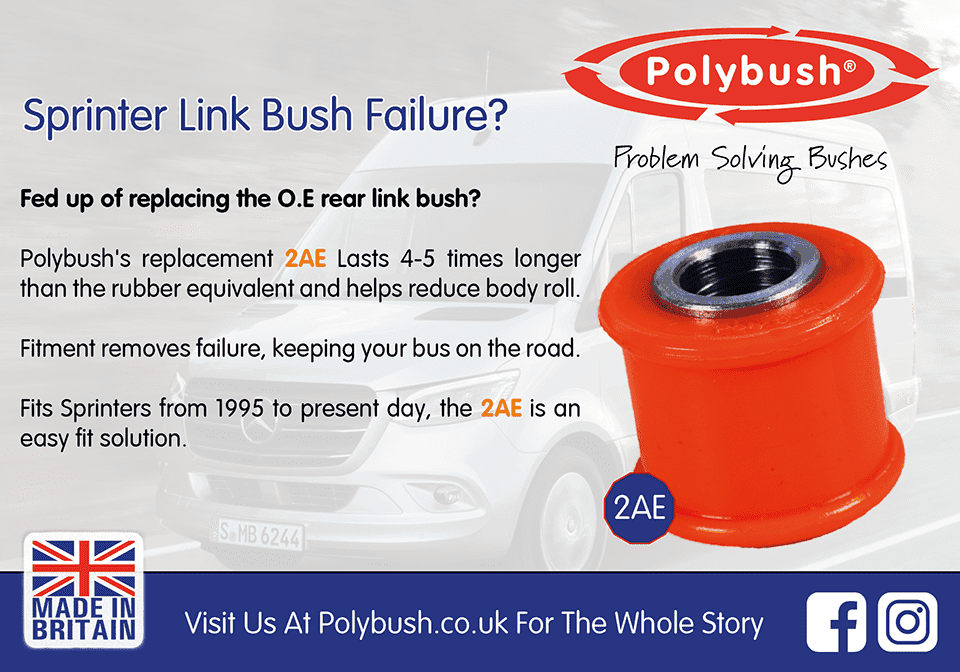

Mercedes Sprinter Link Bush Failure

18 February 2024

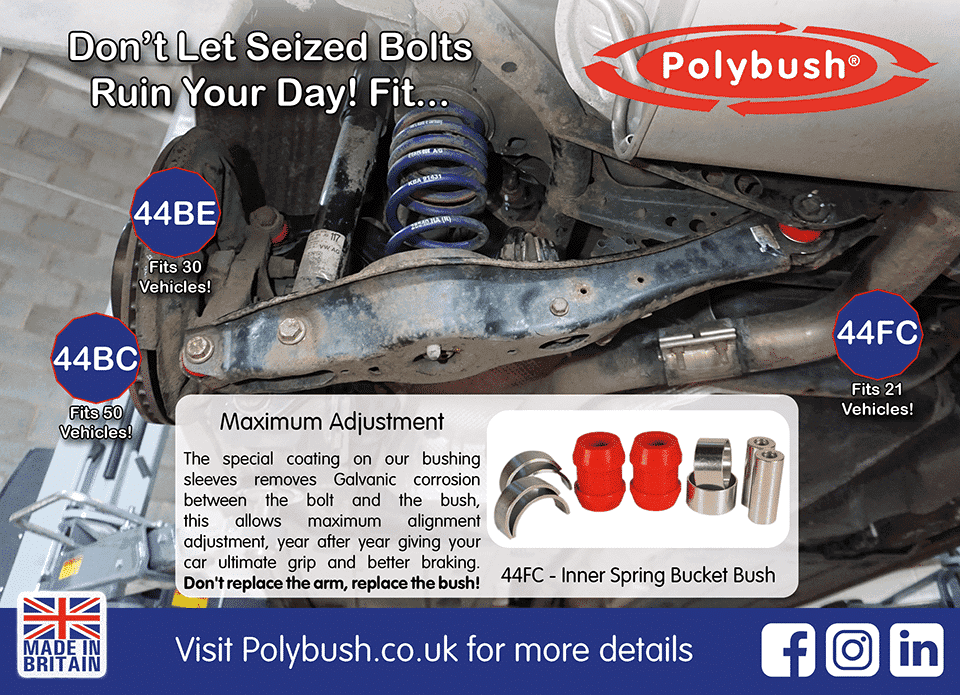

No More 5Q0-505-171 Failure With 44FC

13 February 2024

Transform Your Car *VAG: Say Goodbye to Suspension Failures with Polybush

22 January 2024

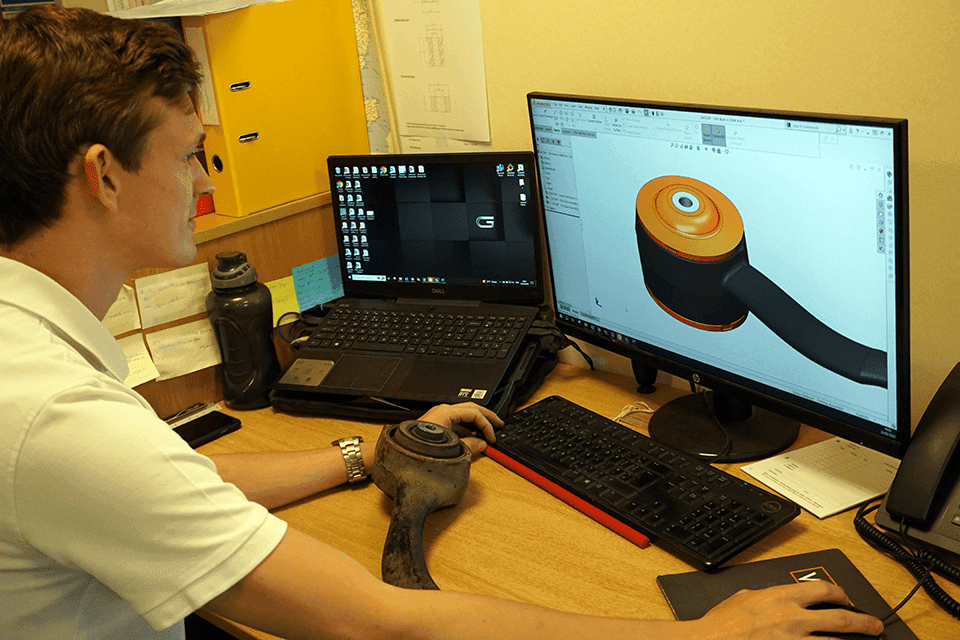

Custom-Made Bushes for Unique Projects at Polybush

30 December 2023

Mastering Precision: A Deep Dive into Polybush Kit 37 for Triumph GT6 Owners

21 December 2023

Polybush Joins The Party: A Toads Night Out

12 December 2023

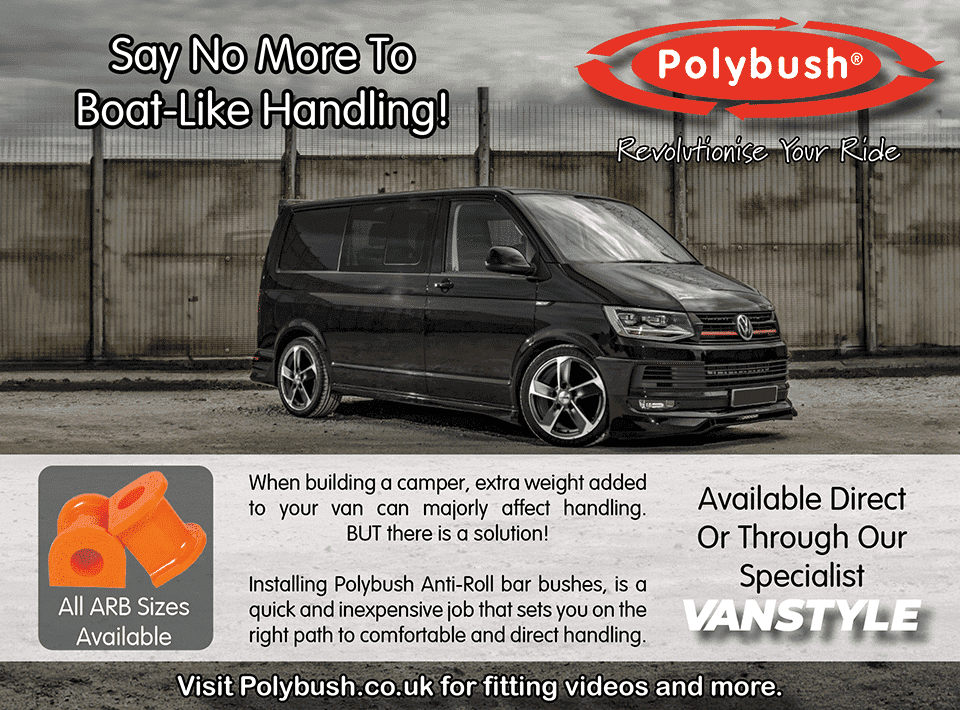

Improve Your T5 & T6 Camper: The Power of Polybush Anti-Roll Bar Bushes

6 December 2023

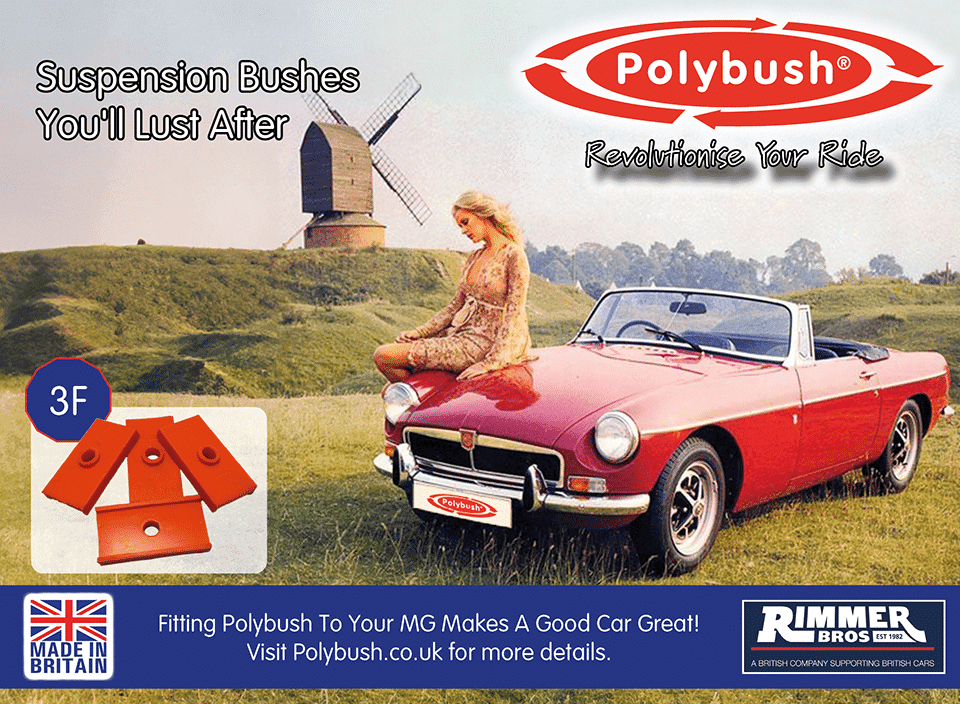

The Goldilocks Zone: Polybush’s Dynamic Grade Bushings Strike the Perfect Balance for MG BGT Owners

27 November 2023

Restoring the Essence of the Austin Healey 3000: A Polybush Upgrade

21 November 2023

Unlocking the Secret to Ford Mondeo (07-15) Suspension Woes: Polybush 40DE Holds the Key

17 November 2023

The 4CA Solution for Iveco Daily Mk6 Front Wishbone Bushes

14 November 2023

Polybush and Kroymans NL: Custom Solutions for the Fisker Karma

Polybush and Kroymans NL: Custom Solutions for the Fisker Karma

20 October 2023

Upgrade Your MG F’s Performance and Comfort with Polybush

Upgrade Your MG F’s Performance and Comfort with Polybush: A Comprehensive Guide

12 October 2023

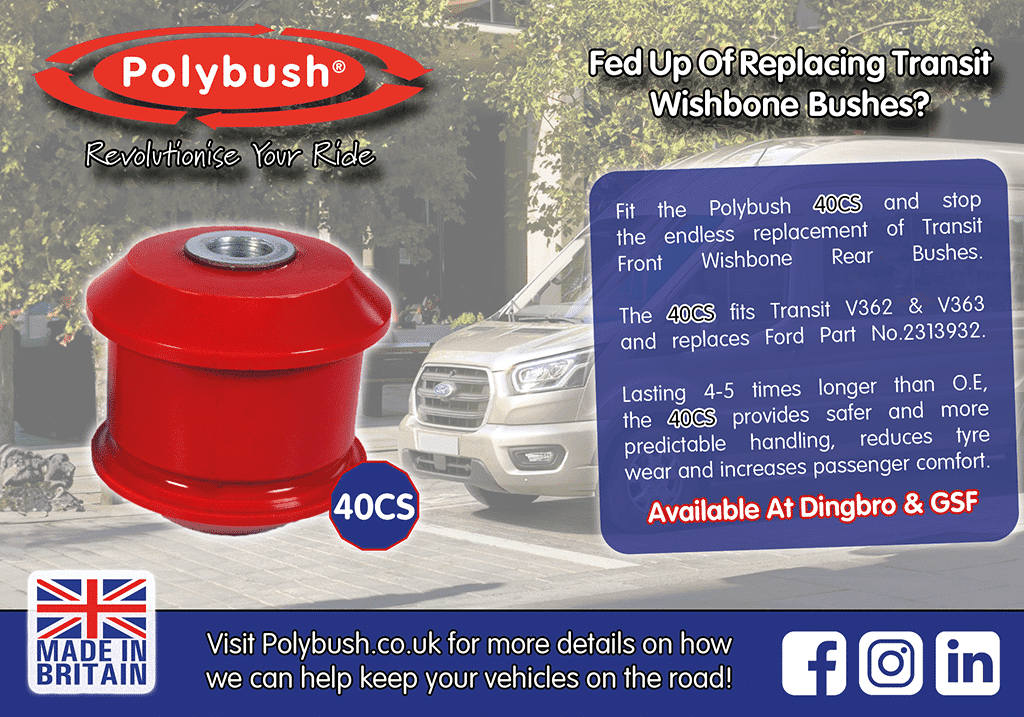

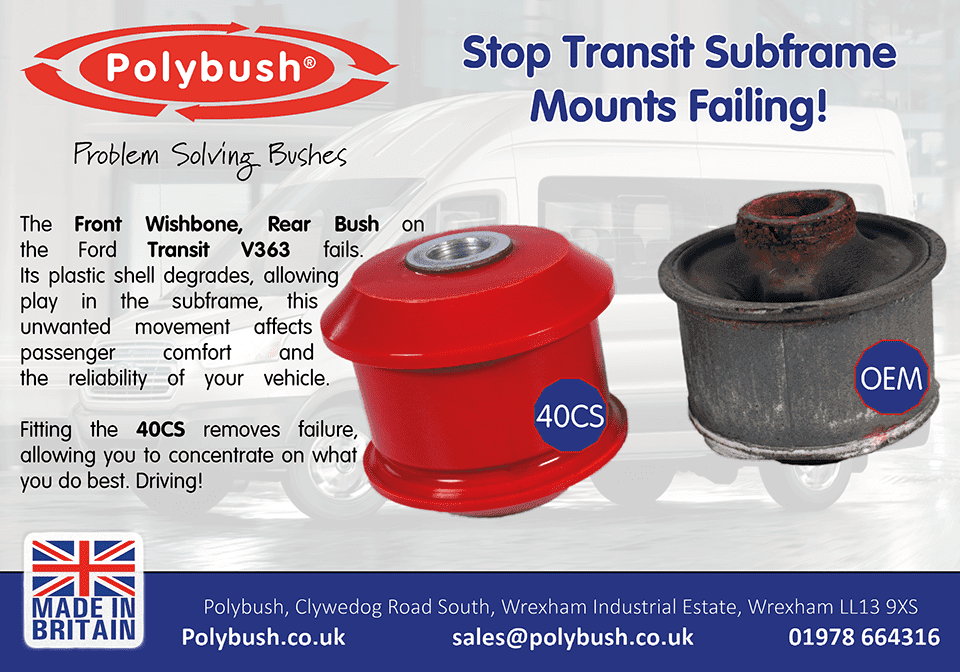

The Polybush 40CS Front Wishbone Rear Bush For The V362 & V363

9 October 2023

CLASSIC MOTOR SHOW: 10-12 November 2023

6 October 2023

Unleashing the Full Potential of Your VW T5 & T6: The Polybush Upgrade

19 September 2023

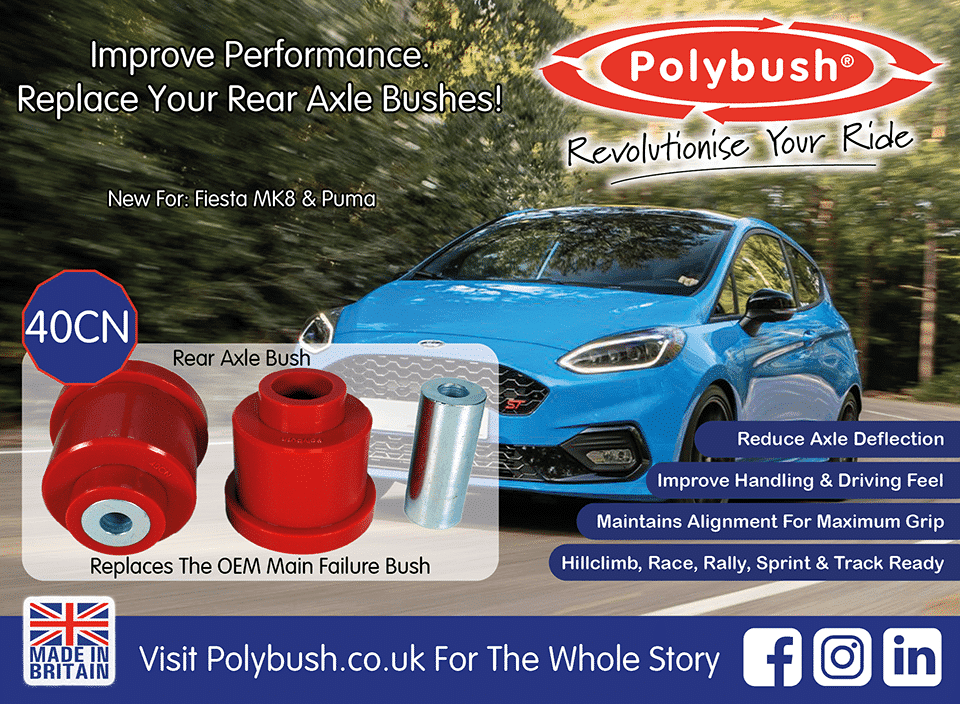

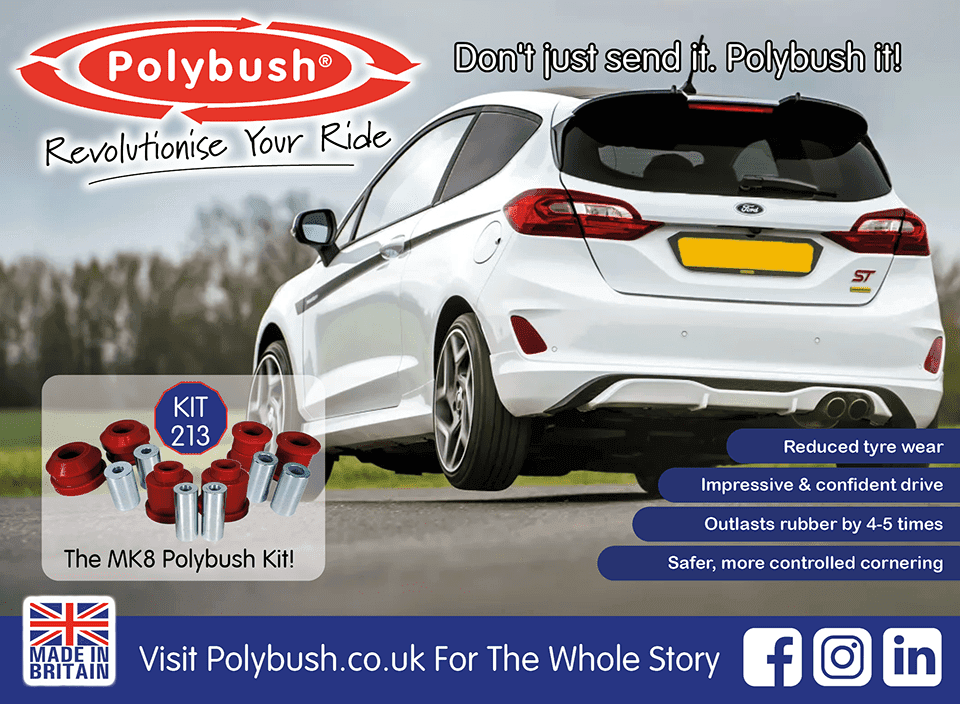

NEW PRODUCT: Polybush 40CN Ford Fiesta Mk8 Rear Beam Bush

16 August 2023

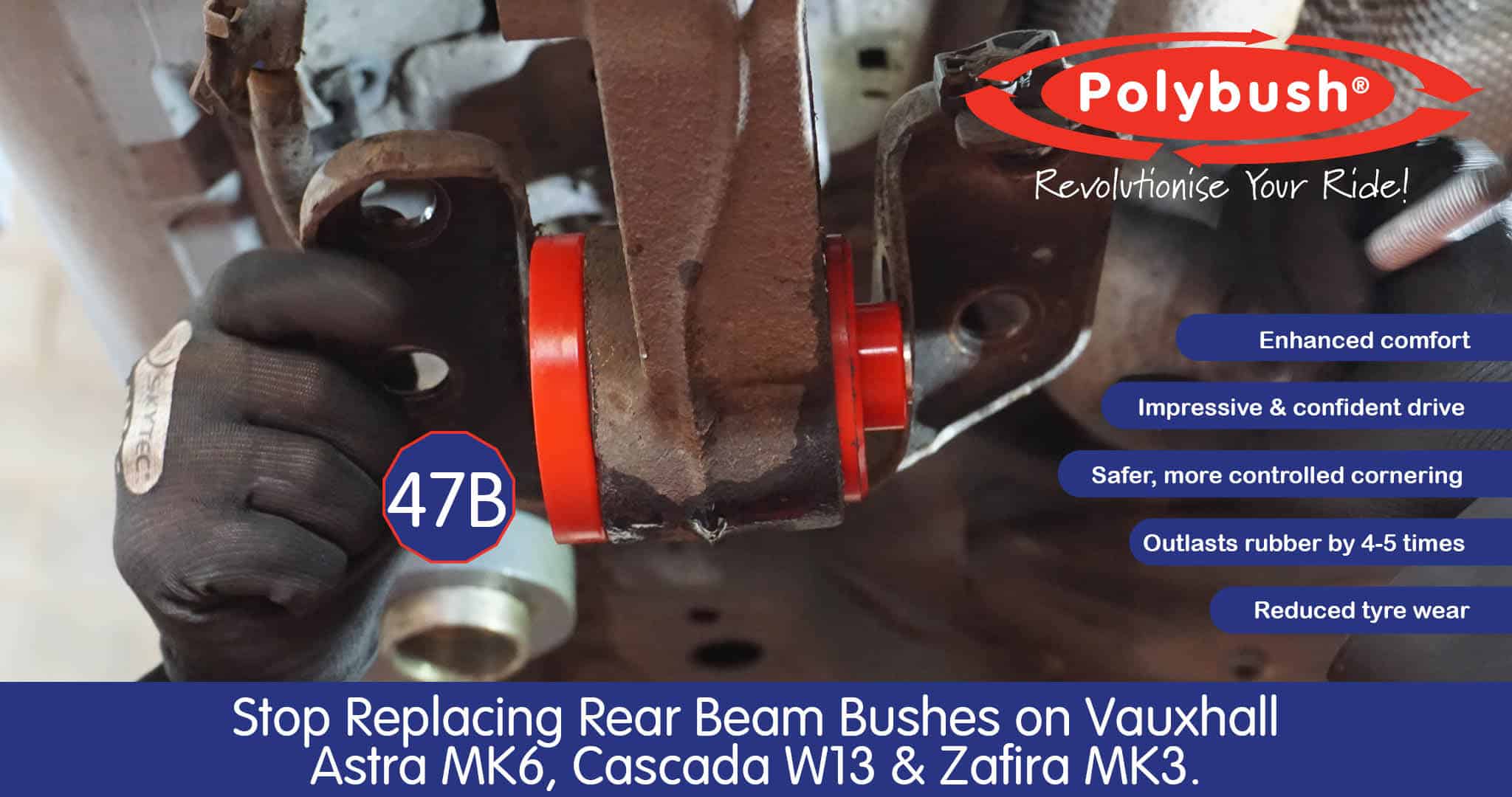

NEW PRODUCT: No More Rear Beam Failures With 47B For Vauxhall Astra, Cascada & Zafira

14 August 2023

NEW PRODUCT: Premium Polyurethane Suspension Bush Kits for 40 PLUS Audi, Seat, Skoda, and VW Models

11 August 2023

Enhance Your Jaguar XK150 Experience with Polybushes: Unleash the Power of Polyurethane!

20 July 2023

Polybush 44M: The Game-Changer for Taxi Fleets

Revive Your MG BGT’s Comfort and Handling with Polybush

13 July 2023

NEW PRODUCT: Save Thousands on Wrightbus Gemini 2 with Polybush 50A & 50B Gearbox Mounts

5 July 2023

NEW PRODUCT: Land Rover Defender Rear Light Boot

30 June 2023

NEW PRODUCT: Enhancing the Ford Fiesta MK8 with a Polybush Suspension Bush Kit

13 June 2023

Elevate Your VW Golf Mk2 with Polybush for Enhanced Comfort and Performance

5 June 2023

Automechanika 2023

31 May 2023

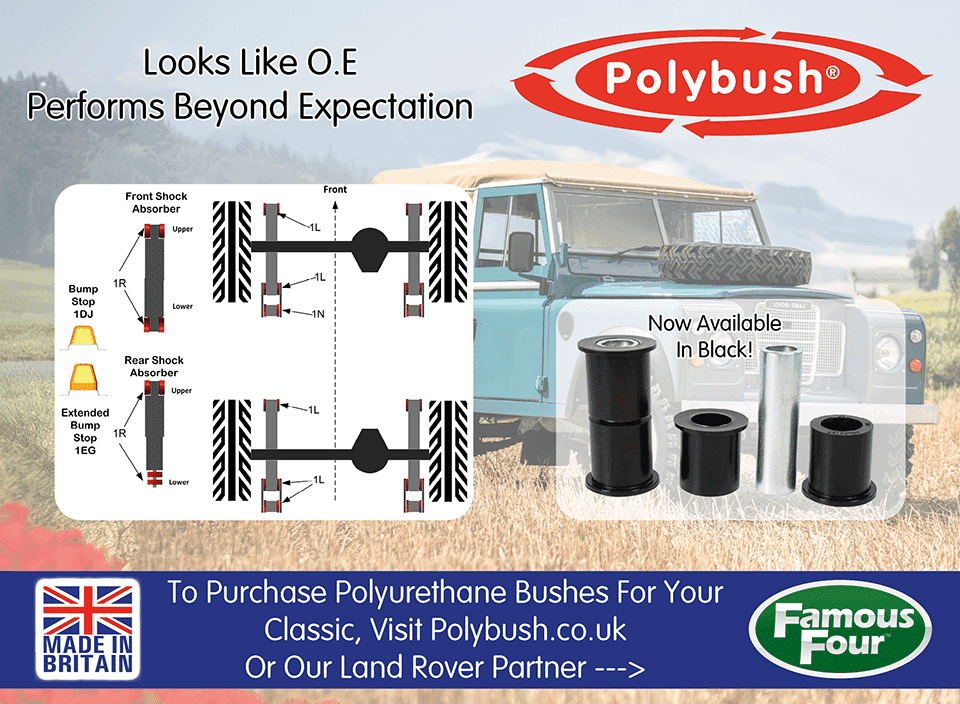

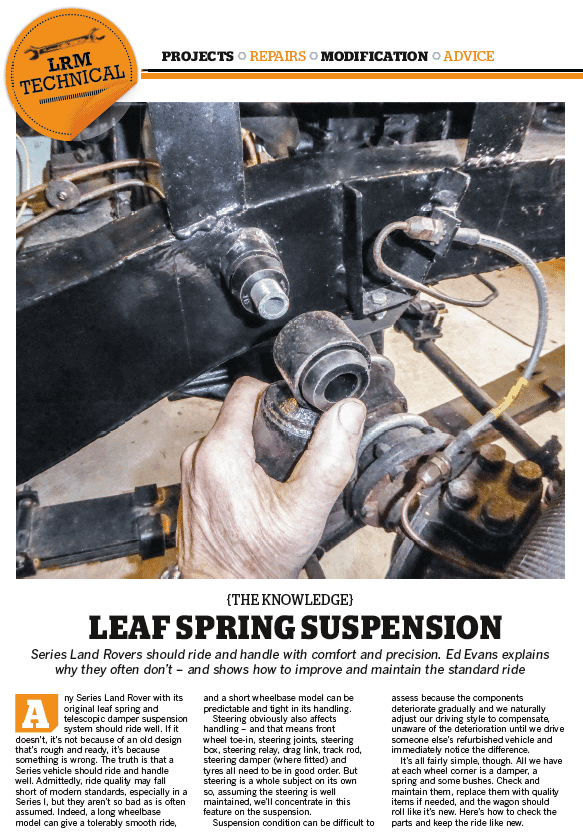

Understanding Polybush’s Different Material Grades for Land Rovers: Comfort, Dynamic, and Performance

25 May 2023

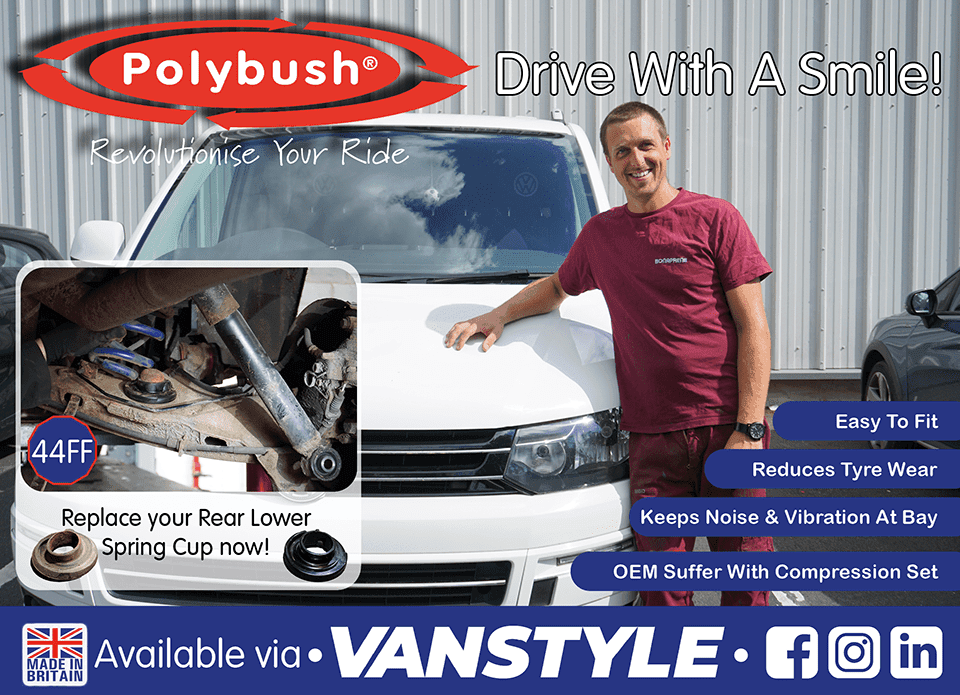

NEW PRODUCT : VW T5 & T6 44FF – Rear Lower Spring Cup Bush

24 May 2023

HOW ITS MADE – Front Lower Arm Bush – Range Rover, Sport and Discovery 5

23 May 2023

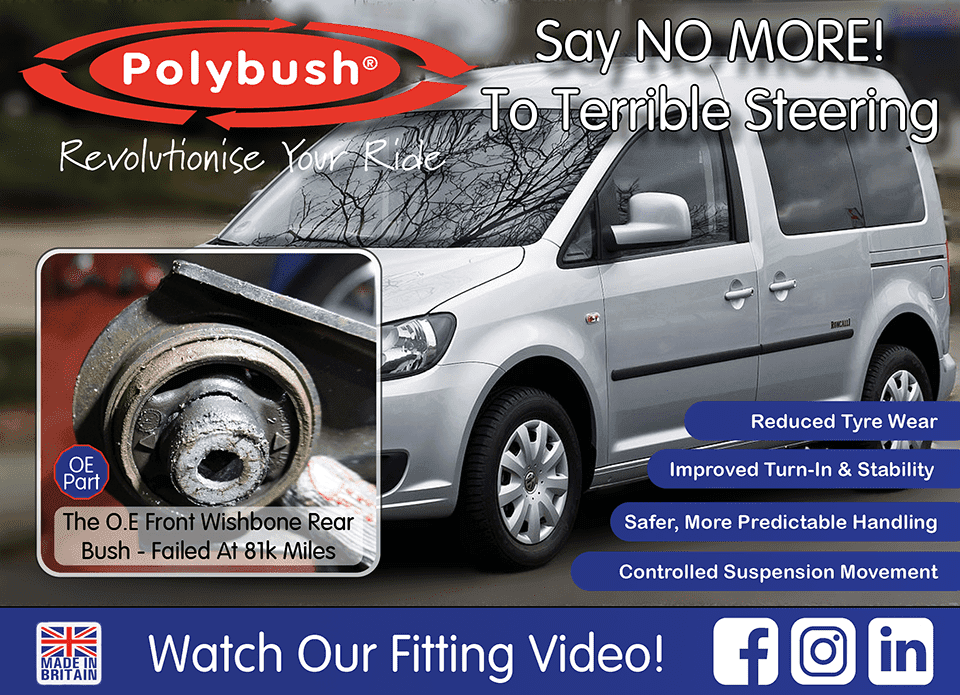

Upgrade Your VW Caddy Suspension with Polybush: Enhanced Performance without Compromising Comfort

9 May 2023

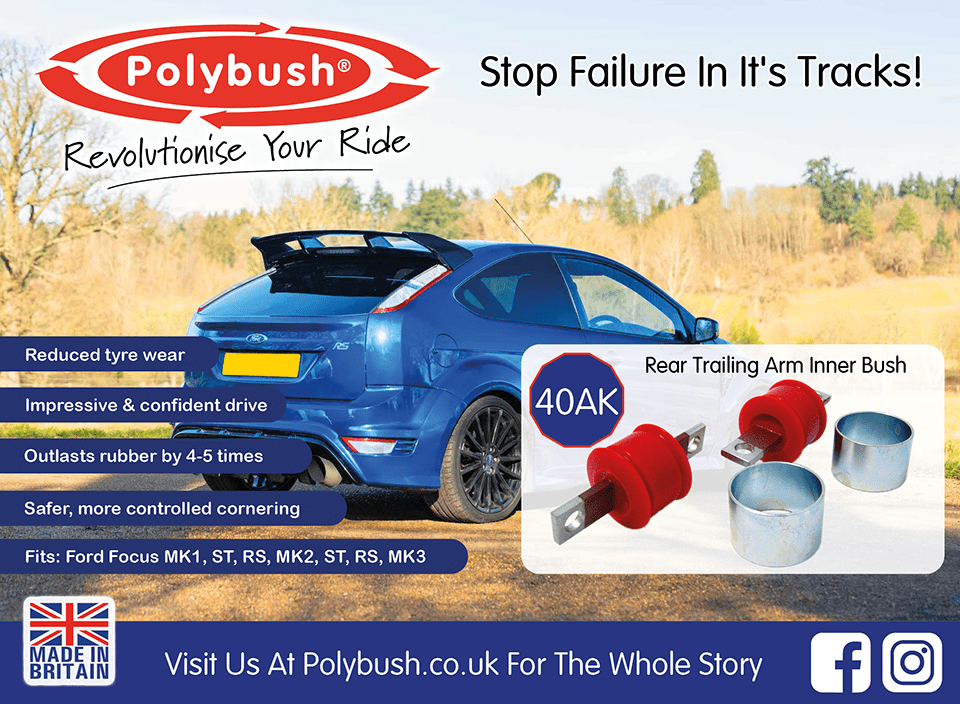

40AK – Stopping Failure In Its Tracks On The Ford Focus

Advice Blog, Commercial, General

5 May 2023

NEW FITTING VIDEO: VW T5 & T6 – Front Lower Wishbone Bushes

27 April 2023

NEW: 2023 LCV Catalogue

24 April 2023

Mercedes Sprinter Minibuses – Link Bush Failure

YARIS GR – Make A Great Car, BETTER!

18 April 2023

Ford Transit Front Wishbone Rear Bush (Subframe) Failure

12 April 2023

Should You Polybush Your Triumph TR6?

24 March 2023

Why Fit Polybush Steering Rack Bushes – Ford Escort MK2

21 March 2023

Why should you fit Polybushes to your VW T5 or T6?

15 March 2023

Why should you fit Polybush to your MG BGT

Land Rover Discovery 3 & 4 – The Main Failing Bush!

28 February 2023

VAG Front Wishbone Rear Bush Failure: SOLVED With 44M

15 February 2023

NEW DISTRIBUTOR: VANSTYLE

2 February 2023

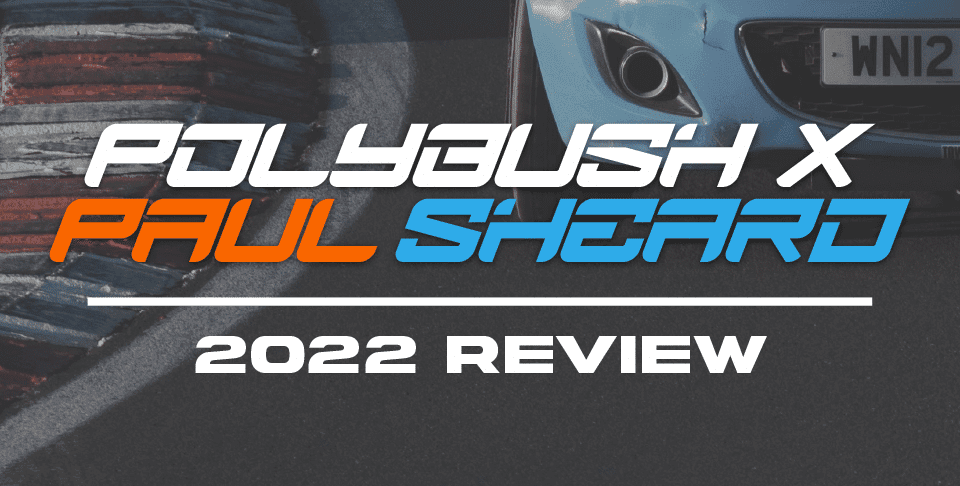

Polybush & Sheard Autosport – 2022 Round-up

8 December 2022

In The Mag – TEGIWA

24 November 2022

In The Mag – Motorsport Magazine (SNG Barratt Takeover)

28 October 2022

In The Mag – Land Rover Owner

19 October 2022

Classic Car Show 2022

12 October 2022

Polybush MX5 Racecar Livery – Paul Sheard Racing

5 October 2022

Frank Elson’s LRO Show Story 2022

3 October 2022

Polybush Featured in Professional Motor Mechanic Magazine!

23 September 2022

LRO Show 2022 – Roundup!

1 September 2022

LRO SHOW 2022

17 August 2022

NEW PRODUCT: MX5 Exhaust Mount Bushes

3 August 2022

NEW PRODUCT: VW Transporter T5 & T6 Polybush Kit 211

29 June 2022

NEW PRODUCT : Discovery 5 L462 – Range Rover Sport L494 & L405

17 June 2022

NEW: MX5 Door Bushes

24 May 2022

Commercial Vehicle Show – 2022

25 March 2022

Triumph TR6 – Suspension rebuild, Live at the Practical Classics Restoration Show

9 March 2022

Practical Classics – Classic Car & Restoration Show – NEC

24 May 2021

Kit 210 Solves MX5 MK4 Hub Bush Failure!

16 February 2021

Range Rover Sport L494 & Vogue L405 Polybush Kits

ST-XR CHALLENGE

POLYBUSH TRIUMPH BONNET LOCATOR CONE

15 October 2020

POLYBUSH AT THE CLASSIC CAR SHOW

GTI INTERNATIONAL

GOLF R32 – Fitting a bush kit

FORD ESCORT MKI & MK2 BUSH’S

POLYBUSH ON THE TRACK – TDI NORTH

LIVE ACTION @ AUTOSPORT 2012

AUTOSPORT 2015 – ARTICLE

POLYBUSH AT THE NEC RESTORATION SHOW

NEW FIESTA POLYBUSH RANGE

BILLING 25TH ANNIVERSARY

PETERBOROUGH 2015

LAND ROVER L322 RANGE

The Ultimate Solution for Mercedes Sprinter Fleets: Polybush Polyurethane Bushes

MERCEDES SPRINTER ANTI ROLL BAR BUSHES

NEW POLYURETHANE POS CAR

TDI NORTH, POLYBUSH AND THE VTECH CHALLENGE

POLYBUSH EXPANSION

POLYBUSH AT THE CLASSIC CAR SHOW 2016

START OF THE SHOW SEASON FOR POLYBUSH

CLASSIC LOOK BUSHES FOR VW

44CF VAG FRONT TOP MOUNTS

BLACK LAND ROVER SERIES BUSHES

COUNTDOWN TO AUTOMECHANIKA 2017

POLYBUSH AND PRACTICAL CLASSICS AT THE RESTO SHOW

POLYBUSH AT KELMARSH SHOW 2017

POLYBUSH AT THE LRO SHOW 2017

POLYBUSH AT SANDOWN PARK – MECHANEX

POLYBUSH AT THE 2017 CLASSIC MOTOR SHOW

PRACTICAL CLASSICS AT THE 2017 CLASSIC MOTOR SHOW FT.POLYBUSH

POLYBUSH REVIEW OF THE CLASSIC MOTOR SHOW

POLYBUSH BLACK SERIES LAND ROVER BUSHES IN LRM

BUMP STOPS FOR SERIES LAND ROVER NEW!!

POLYBUSH AT THE PRACTICAL CLASSICS RESTO SHOW 2018

14 October 2020

KELMARSH 2018

KELMARSH 2018 SHOW REVIEW

2 FREE TICKETS TO THE LRO SHOW

GOING GREEN FOR 2019

CES STAFF MEMBER AWARDED SALES PERSON OF THE MONTH

A HIGHLIGHT OF 2018 – THE LRO SHOW

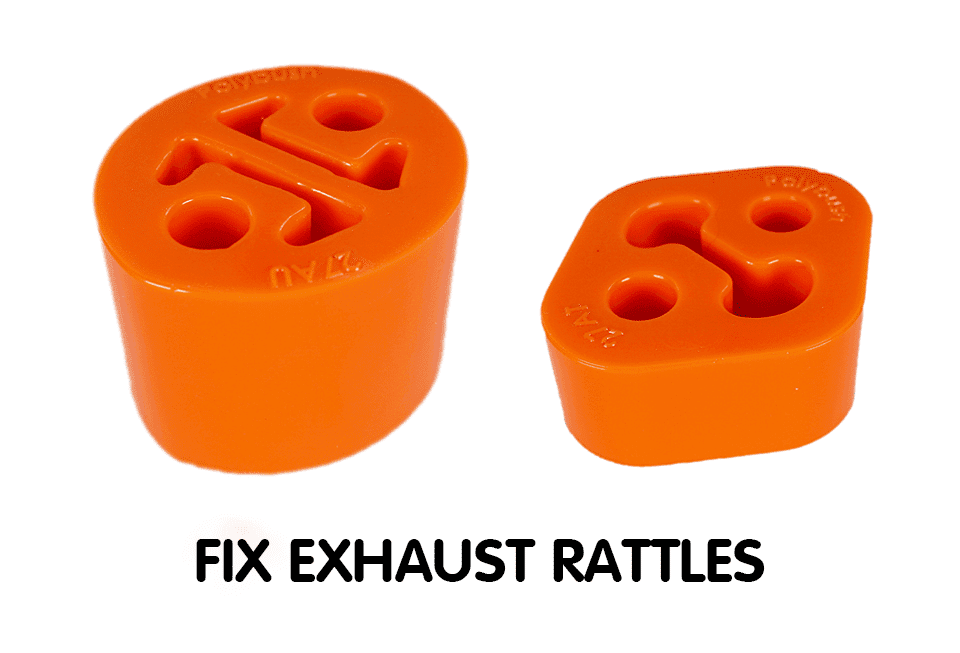

LONG LASTING POLYURETHANE EXHAUST MOUNT REPLACEMENT 41AW CREATED TO TOP OE STANDARD PART.

BUSH KIT DESIGNED TO COMPLEMENT AND IMPROVE UPON THE FANTASTIC PERFORMANCE OF THE CIVIC FK2

SUMMER IS AROUND THE CORNER… NEARLY!

THE CLASSIC CAR AND RESTORATION SHOW 2019

SPONSORING TWP RACING

LRO SHOW PETERBOROUGH

CLASSIC MOTOR SHOW 2019

KELMARSH LIVE RESTORATION- LAND ROVER MONTHLY

PRODUCT OF THE MONTH- ANTI-ROLL BAR BUSH

TR7 RESTORATION – GOOD VIBRATIONS

PRODUCT OF THE MONTH! – BUMP STOPS

NEW PRODUCT RANGE! – ISUZU D-MAX

FEELING NOSTALGIC? HERE’S A THROWBACK TO 2003

PRODUCT OF THE MONTH – WISHBONE BUSHES

More durable Enviro 200 Shock absorber bushes for Alexander Dennis.

Unparalleled Products backed by outstanding customer service.

Need help? Speak to our experts

Need help? Speak to our experts

Get in Touch

Take a look at our contact page to find the best way to contact our dedicated team of experts.

Useful Information

Access the most up-to-date industry advice and techniques for installing and utilising our top-tier suspension bushes.

Need Help Choosing?

Searching for the perfect suspension bush can be overwhelming. That’s precisely why we’ve put together a helpful guide to assist you.

Unparalleled Products backed by outstanding customer service.

Need help? Speak to our experts

Need help? Speak to our experts